G11 no CAN contact but tablet/smartphone communication

G11 no CAN contact but tablet/smartphone communication

Hi,

I'm doing some tests on a MC43 and G11 antenna. I managed to update the program in the MC43 through IQANSync with smartphone (so thanks to G11).

I also connect to IQANRun Free with the tablet, I can see parameters from the MC43, but it says that there is non contact with G11. How can it be possible because I know this thanks to the G11 antenna ?

Can it be a programming problem ou physical problem ?

Thanks for your answers.

Bidirectional Prop. Valve input

Bidirectional Prop. Valve input

I have an MD4-5 and XC-21. Another measurement system gives output for 2 bidirectional prop valves. (24V 3Amax.) how can I measure this values with one of the modules?

The max current in is limited to a few Mili amps and the voltage in is limited to 5vdc.

PWM could be an option but there ate only 3 available on the xc21

Tips are welcome!

Multi-Master Settings Revert to Default on Upload

Multi-Master Settings Revert to Default on Upload

I'm not sure if this is a bug or not, but we had an issue in the field where a new program was uploaded to a multi-master system. The system has two MD4 displays (one -7 and one -5) connected on a master bus. The new program was sent via IQAN Run. After the upload, all the stored settings for the MD4-5 reverted to their default values. The PC was connected directly to the MD4-7 with the MD4-5 connected via CAN bus. Re-loading the previous clone file did not resolve the issue. This created quite an issue because service personnel do not have access to the "master" settings of the machine. Does anyone know how this could have happened?

baudrate

baudrate

where can I find the Baudrate of one Bus? ( the combined diagnostics, and masterbus? )

Thanks a lot!

Voltage inputs automatically offset by VREF supply?

Voltage inputs automatically offset by VREF supply?

We are using ratiometric voltage sensors for an application, by selecting the reference voltage (A or B) on the controller input, does this automatically offset the VIN with the VREF supply fluctuations?

We know that because the sensors are ratiometric the supply to the sensor will cause the signal emitted from the sensor to change slightly. We have achieved this using code in the application, however i'm just checking the controller does not compensate for this automatically without the need for user configured code? I would imagine it does not do it automatically because there is no option to select its a ratiometric or normal regulated sensor connected to the VIN.

Perhaps this could be a feature we see in a future IQAN Design? I know we would find it useful instead of having separate code. Provided of course the variation % on a ratiometric sensor output is the same for different manufactures of sensor, if they are different, maybe an option to enter some values?

Nmea2000 multi packet J1939

Nmea2000 multi packet J1939

Dear Guys

I would to read Nmea2000 packet. But some PGN is coded which more than 8 bytes. The GPS Garmin send packst following each other.

PGN of 129029 (0x1F805) Mapping :

Maybe I need to use page mask and page value, but I don't find some information.

Regards

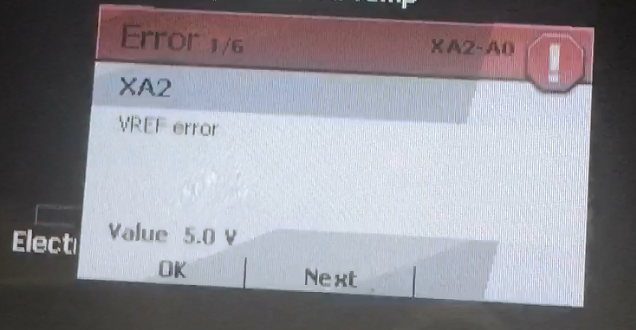

Vref Error

Vref Error

I have 2 reports of Vref Errors and they are reading right around 5V, which is normal, what can cause this? The picture below was taken from a video of one of the customers machines. the other codes are sensors that are picking up and dropping from what i am assuming is the root of the Vref Error.

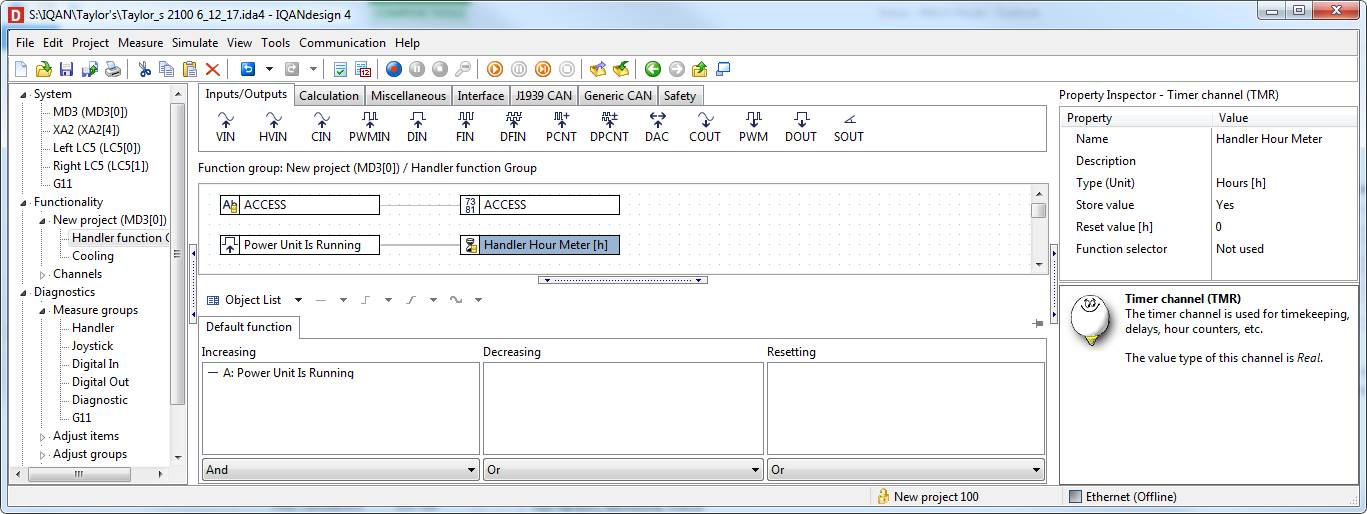

Timer Rest Without Trigger MD3 Hard Reset?

Timer Rest Without Trigger MD3 Hard Reset?

Is it possible that a Timer Channel could reset without being triggered (see below image). I have documentation showing that we sent out a machine with 5 hours, the next reading recorded was 3 hours. Our Service tech recalls seeing the screen flash and reset.

MC43 Digital Inputs staying true with nothing connected

MC43 Digital Inputs staying true with nothing connected

All inputs are configured as Digital inputs – AM, AN, AO, and AP and are staying true no matter what is connected (we pulled out the pins and they are still true).

These are Pins C1- 11, C1-12, C1-13, and C1-27. They are all staying true and seem to be outputting 4.6V.

Have you seen this before?

We have tried 2 different MC43’s with the same results.

I am using the latest version of Iqandesign 4.07 if that matters.

md4 wil not take logs when I send clone

md4 wil not take logs when I send clone

MD4 does not update its logs when I send the clone file.

- The clone file contains logs.

- This clone file is from version 4.05.

- My IQANrun is version 4.07.

- I am logged in as Superuser, and I also tried other levels.

- I tried sending a blank ida file, also tried sending other clone files without success.

I'm replacing a damaged MD4 on a machine, and now I'm losing all of the machine's statistics and events. The new MD4 actually previously had version 4.07 installed.

I was planning to send the clone with logs (4.05), then send a new IDA at version 4.07.

Customer support service by UserEcho