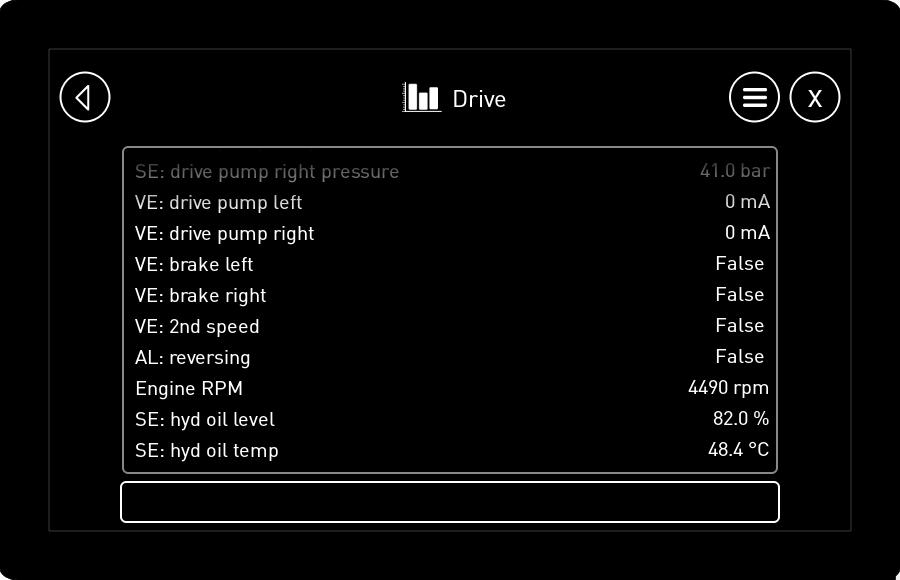

Measure display widnow

Measure display widnow

Is it just my impression or the values on the second picture are more readable?

Is there any reason why values and units are connected? While using the multimeter in IQANdesign I started to think about it ...

IQANsimulate screen capturing

IQANsimulate screen capturing

Is there a way to do a mass export of all screens in IQANsimulate? Investigating for our technical publications team who want to save time documenting programs.

Integer Parameter Adjust Item

Integer Parameter Adjust Item

I have an adjust item integer parameter that is user definable through a MD4. The value varies from 50 to 112. I want to display that value in an interactive message. The interactive message shows up when the integer parameter is different from what the previous value was. The previous value is stored in a memorizing channel. The problem I am having is that as soon as the adjustable integer parameter is changed, and it is different from what is in the MEM channel, the message grabs that first different value to display in the message. For example, the default value is 112 and I want to change it to 105. The message comes up and says 111 instead of 105 because it took the first different value. Is there a way to make the adjust item parameter only change values if you press the check mark to confirm?

IQANsimulate and MD3 images/text display issue

IQANsimulate and MD3 images/text display issue

I have encountered a weird occurrence when doing simulations with MD3 on IQANdesign 5.03.

It appears that especially "LAMP" images or text does not does not (always) load when switching between display pages. BUT the images/text are actually loaded but not visible and will only appear once I have minimized the IQANsimulate window and restore it again, then all the graphics appear and react as it should... Until I go to another display page again and have to minimize and restore the window again to see the actual result.

Has anyone else encountered this before? I have not yet noticed this behavior using the MD4 displays.

This is kind of interfering with my debugging progress (trying to fix things that is not broken).

I haven't tested to see if this occurs on the actual hardware yet, but I am sure this problem is limited to the simulation only.

Memorizing Adjust Item

Memorizing Adjust Item

EXAMPLE PROJECT

IQAN Design 5.02

I was working on setting up a slider on a display page that set the value of a memorizing adjust item. After adding the memorizing channel to a function group and dragging it into the adjust items, I was having issues setting the input of the memorizing channel. I was receiving an "Undefined Reference" error and since it was in an error state I couldn't set the input to refer to itself. The work around was to first select a math channel as the input of the memorizing channel and then it would go out of error state and I could set the memorizing channel to use itself as an input.

MD4-VDIN to MC43-DOUT

MD4-VDIN to MC43-DOUT

Does someone know how to make a VDIN (virtual digital) on an MD4 to control a DOUT (Digital out) on MC43?

I get the warning “Channel assigned to an unreachable module”

Memorized Array / EEPROM question

Memorized Array / EEPROM question

Not sure how memory-writes work in IQAN, so wWe were wondering if large (4096 elements) could be a potential problem.

A large array is used to store adjustable settings, coming from an input terminal. We don't have that many parameters really -typically 100 or so- but we use ID-number-referencing to quickly SET/GET a stored value.

To my knowledge, EEPROM writes should be limited as much as possible. So if I change one element in this array, do all 4096 elements get rewritten into EEPROM, or just that single spot? Or to put the question differently is it recommended to use separate Memorize channels instead of big arrays? The reason we chose arrays is to quickly code stuff, regardless if there are 10 or 1000 parameters.

And about limiting, when does IQAN actually write its EEPROM? As soon as something changes in an Array or when a Memorize channel is triggered, or does it do some smart stuff behind the scenes?

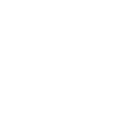

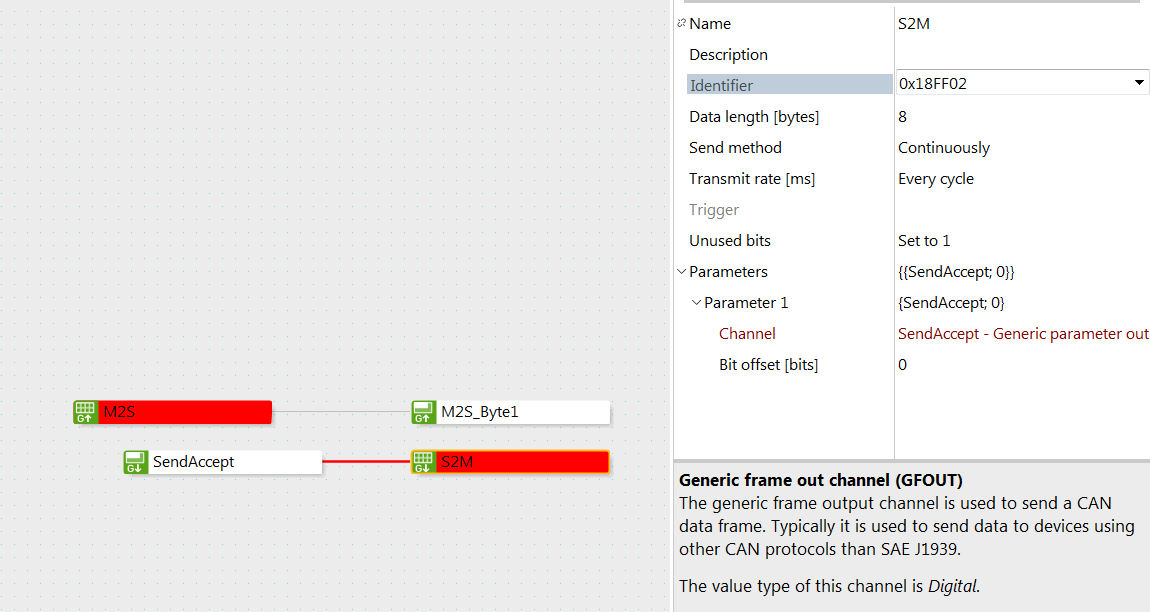

can identifier not within limits

can identifier not within limits

Hello,

Fairly new to the Iqan design... When I try to receive a Can Message (generic 29bit identifier) with ID 0x18FF01, the ID is said to be out of range??? But my ID is in the ID range?!

Thanks for the help in advance

Regards

Davey

DerivitiveOf

DerivitiveOf

When using the DerivitiveOf function on a value that stems from a CAN message coming in less than every cycle, the derivitive is incorrect because the time over which the change occured is not a single cycle time. We have been using a timer to calculate the rate of change. I am not sure if there is a simple solution for this but it would be nice. Perhaps it could use a flag from the CAN frame and calculate the time between them, or something like that.

iQanDesign 5.x and brand new MC2 unit program download

iQanDesign 5.x and brand new MC2 unit program download

I tried today to download a 5.x program into a brand new MC2 unit who have never been upgraded with a new firmware. (Actually, I used 5.03 version)

I always go no communication with the MC2 until I use a V4.x iQan design.

After the first firmware update from 4.07 iQanDesign, I was able to complete the task from the 5.03.

There is an issue with this version ?

Customer support service by UserEcho