MD3: USB upload --> IQANdesign: "internal error"

MD3: USB upload --> IQANdesign: "internal error"

We have 3 win10 laptops running IQANdesign. All 3 does have exactly the same version of IQandesign, but it seems that only the one laptop struggles to communicate via USB, IQANdesign prompts "internal error" when attempting to upload the software.

Has anyone else came across something like this or is there just something I have to set in IQAN or windows?

Missing CAN traffic info on Iqan Design 5.03?

Missing CAN traffic info on Iqan Design 5.03?

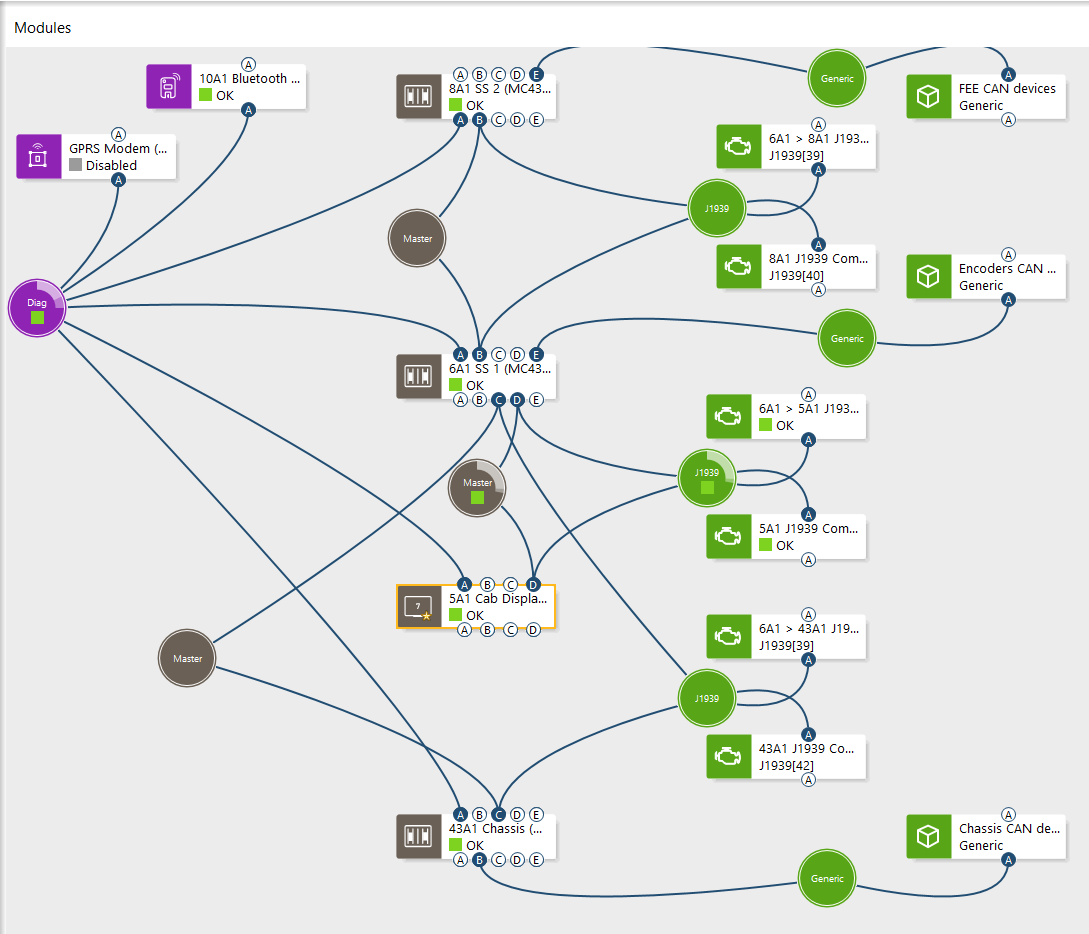

When monitoring CAN traffic in 5.03 using the system overview part of the software, I am unable to see traffic and health status (green box) on some of the busses and modules. Sometimes clicking on one that is showing traffic OK makes the gauge and status disappear and have to click away from the system layout page to get it back again. Its almost as if the program will only show one of each type of bus from the display module only. Is this normal? Would be handy to be able to see gauges and status on all busses and modules in the system.

Using CAN USB device connecting laptop to diagnostic bus which is linked to all the modules in the system.

IQAN connect license on IQANRun

IQAN connect license on IQANRun

Hello,

I bought IQAN Connect licenses that I downloaded on my computer. When trying to connect via Internet, I have A License Status : Unknown. I can't click on License status to update the license, the link doesn't seem to work.

I also tried to open the license file with IQANRun and IQANDesign with no more success.

How can I do to use the remote assistance ?

Thanks in advance !

Socket error #111 - Connection refused

Socket error #111 - Connection refused

Hello,

I'm trying to connect my Android Phone to the G11, and connect machine to Internet. When I connect with the G11, I have an error message Socket error #111 Connection refused.

I have not buy IQAN connect key, can it be the problem ?

Thanks in advance.

Qcode vs Object List Affect on Ram Usage

Qcode vs Object List Affect on Ram Usage

I have a program that is at the limit of the available RAM in our master unit. I haven't made use of Qcode much but am wondering if I replace my object list logic with equivalent Qcode on a large scale will it result in lower RAM usage?

Thanks,

licence name

licence name

Daft one - I misspelled my name when registering my IQAN software. Do I need to uninstall/reinstall to change the username it's registered to, or is there a hot fix for this?

Andy

Programming/upgrading controllers require security login

Programming/upgrading controllers require security login

We got a question from our service guys that when they upgrade a program on a system to the latest revision that this particular version is asking for one of the usernames and passwords from the security section. Not the limited or full password but a user one.

The only thing I can think would cause this is I added an adjust item in this latest revision that requires the user login from above. Could programming a previously programmed system that DIDN'T have said adjust item(requires user login to change) to a version that now has said adjust item cause the individual programming the truck with IQANrun need to login with a security user/pw ?

MD3/MC42 multi master trouble

MD3/MC42 multi master trouble

Hi everyone.

I have encountered a strange problem with a MD3/MC42 multi master system and cant't seem to resolve it "quickly".

The problem is that I cannot upload the software onto the system effectively. I have used MD3's and MC42's quite a lot in the past but never together like in this manner and this is the 1st time I encounter this issue (usually I have a MD3 with an expansion module or either a MC42 with a MD4 multi master system with no problems) so this time we wanted to use the MD3 and MC42 together for a project, so I thought it will be basically similar to using a MD4 with a MC42.

I have a 0T id tag on the MD3 and a 1T tag on the MC42, when trying to uplod the software via USB through the MD3 I get the message "incomplete system" and showing only the MD3(Safe mode). But the display also indicated wrong ID tag for some reason.

Then when disconnecting the 0T ID tag from the MD3 and try to upload the software, it works when I click yes after I get this message shown below, both controller get updated though, but then after uploading/startup a message appears on the display stating "CONTROLLER MC42 : NO CONTACT"

Does anyone have an idea what I am doing wrong and where? Am I reading the MD3 manual wrong or something? It states when using it in a single master system no ID tag is required (only a tag on the expansion module if present) but using a multi master system an id tag is required.

I have tested this on 2 different wiring looms also with other new controller modules, all with the same result.

What am I missing here...?

MD4 Crash With Blue Screen

MD4 Crash With Blue Screen

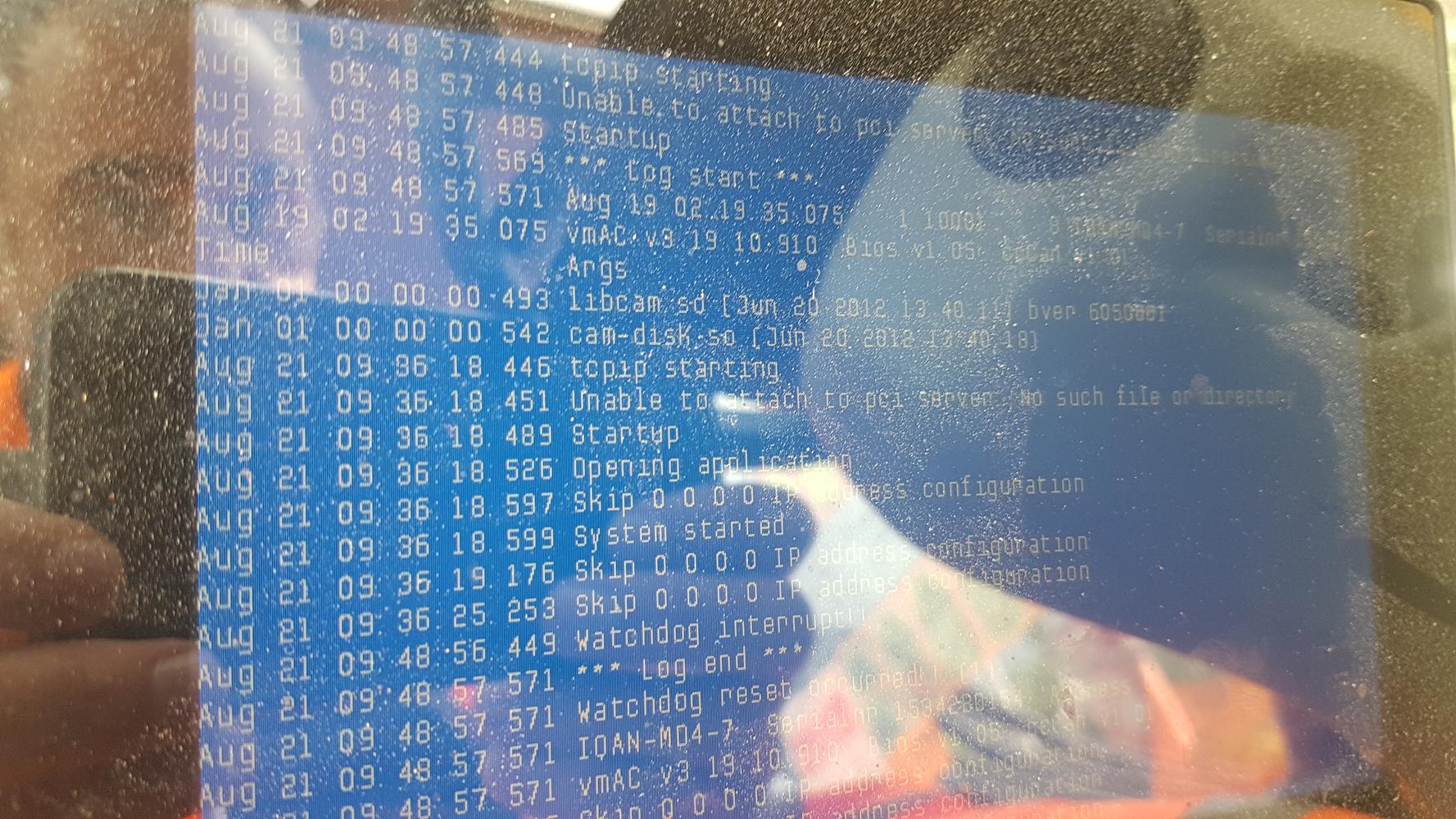

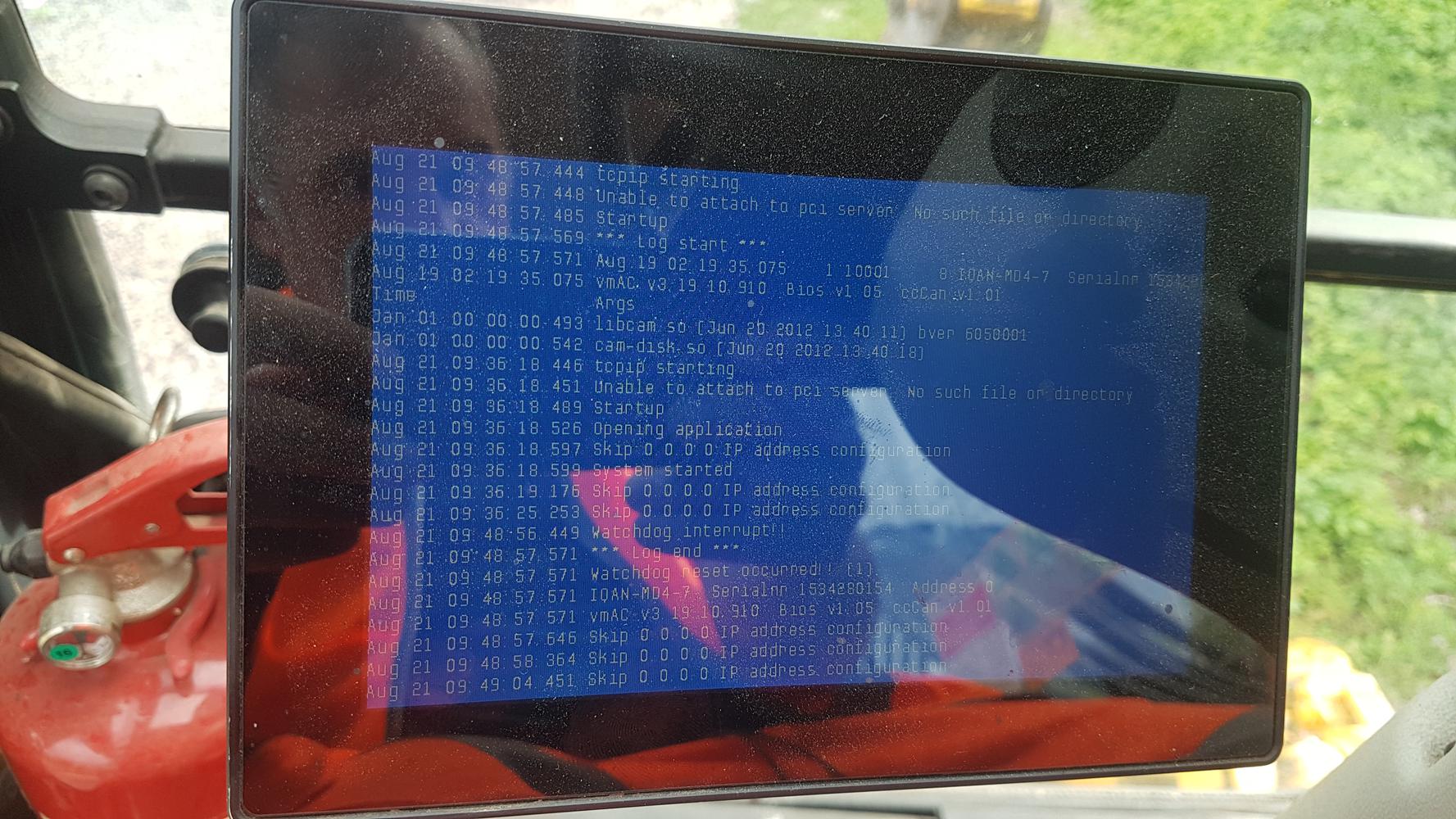

I have a customer with a machine fitted with multimaster 1 x MD4 and 2 x MC3 running 3.19.10 (display is running 3.19.10.910, MC3 running 3.19.9.2170). Randomly with the machine powered and no change of inputs on any modules or touch inputs to the MD4 we get blue screen. The display does not recover from blue screen, and the system needs reboot to clear the error.

Logs in MC3 (number 1) suggest loss of contact with MD4 display and second MC3, no contact. At time of MD4 blue screen i got a diagnostics bus error (wired to bus D on each controller) logged only on first MC3. Second MC3 does not appear to have any no contact errors with any modules. MD4 does not appear to have any no contact errors (dosnt even log the blue screen).

I see there are some old issues found with the V3 software, would the recommendation be to update to version 4.03 initially? We have 10 machines running his software successfully, only this machine appears to be troublesome, they are all running same software and hardware.

We have CAN open device on CAN C, terminated both in display using software termination and also at the node end using resistor.

Password protected actions?

Password protected actions?

Using a MD3 I have a set of "Emergency Functions" to give direct control over the system and bypassing the normal safety over-rides. I did this to allow a malfunctioning truck to return to a safe condition so it can be brought back for servicing and allow for easier servicing.

It function by using various screens and jumping between screens to control different circuits.

I currently have it so you put in the password once to enable these functions by allowing access to these screens, and then they are enabled indefinately.

What I would like to acomplish would be

A. Require a passeword input every time the main emergency function screen is accessed,

or

B. Have the State Parameter that is adjusted to allow the Emergency Functions to be accessed, reset to "disable" with every power down.

I don't think I can do A, but it would be prefered. B should be doable, but I don't see quite how to do it. Do I need to use something other than a state parameter?

Customer support service by UserEcho