multiple camera input

multiple camera input

Hi all

I have a new application requiring multiple SV cameras feeding into a MD4 master. I only need to view one or two inputs at any given time, but all four camera feeds need to be available and switchable at any time. I know i will have to use some form of ethernet switch for the multiple feeds into the C4 port of the MD4, but don't know if this needs to be a managed or un-managed switch? Has anyone out there done this sort of thing with the SV cameras, and if so can you help with the app file in the MD4 and recommend a suitable switch?

many thanks

A

Hello.

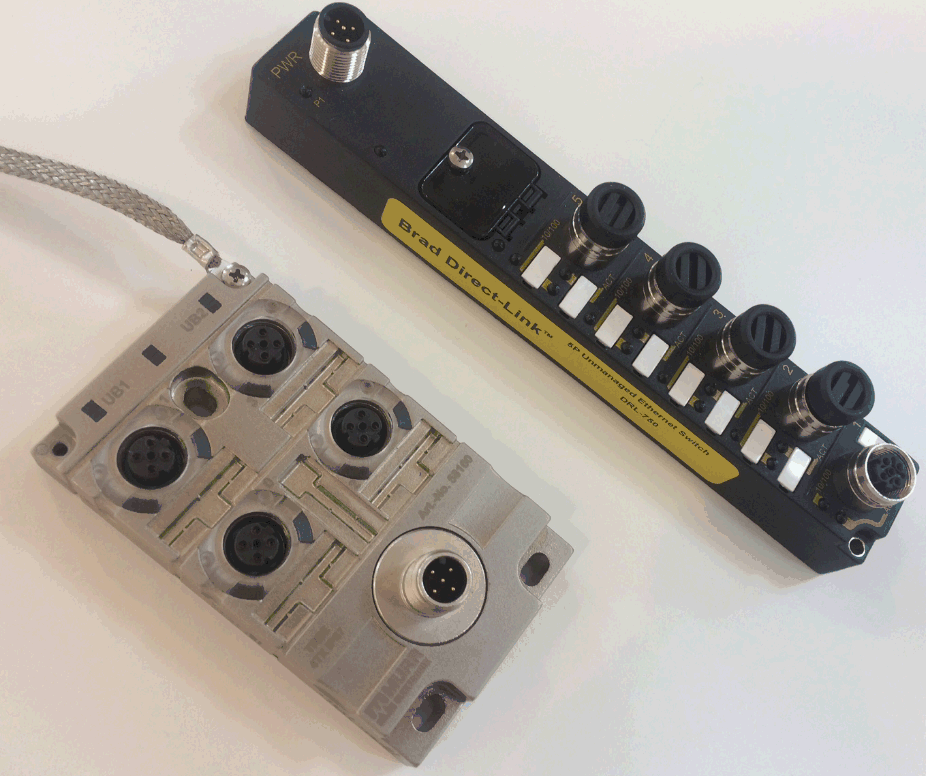

We have done some testing with rugged ethernet switches to see if they work with the MD4 and SV cameras.

They are unmanaged switches so you only connect them and are ready to go.

These two switches were tested with three cameras (only had 3 to test with) and was found to work.

Molex DRL-750Murr

Electronik Art.-No. 58160

Test were also done on 'Moxa TN-5305' and 'Phoenix Contact FL switch 1605 M12'.

These two switches experienced problems when more than one camera were added.

LED light patterns

LED light patterns

Does Parker Hannifin have an LED status/error light pattern guideline for it's products in general?

Hello.

If you look trough the instruction books you will find that the blink panthers have roughly the same meaning on each of the current IQAN products.

The difference is if the unit in question have all the different blink codes or not.

There can also be a difference in the description of the error, this is why i said roughly.

For example, you have the blink code for output error 1:1.

On the MC2 it is only described as 'Output'.

On the XC21 it is described as 'DOUT error (open load)'.

This comes from that the only output on a XC21 is the DOUT and the only error detection we have on it is the open load.

On the MC2 we have more types of output channels that can generate this error so it is only described as 'output'.

These blink codes come from the MC3 instruction book.

Using these you can get a good idea of what is wrong with the unit.

1:1 Output

1:2 Input

1:3 VREF

2:1 Power Supply

2:2 Temperature

3:1 CAN, no contact

3:3 System mismatch

3:4 CAN error (bus off)

4:1 Internal error/OSE

4:2 Critical Temperature

4:3 Critical Stop

Use IQANsync to set Machine ID

Use IQANsync to set Machine ID

It would be nice if there was a way to use IQANsync & a G11 modem to set the Machine ID. We program MD4's in batches, then after installation we have to go back to the vessel with a laptop to save logs, clear logs, and set the machine ID. It's convenient to be able to handle the logs with an iPhone, but we still need to laptop to set the Machine ID.

IQAN SV wireless

IQAN SV wireless

Dear

For railway application, one of my custumer will be interesting to connect the Iqan SV ( camera ) to the display MD4 without wiring. We are looking for “Wireless system”

Do you have a solution ?

Best regards

AXIS F1005-E camera with MD4

The IP camera display functionality is a fantastic option!

Piggyback on J1939 Backbone

Piggyback on J1939 Backbone

PWM Input

PWM Input

I have an application that requires using a PWM input to control the brightness of a MD4 5 inch non-touch display. The input is to be wired on C4:1 of a XC21 module. The input runs at a duty cycle of 10-90%.

Unfortunately for me, this is an optional input on the overall system. It is possible, that the PWM input is not available. If this is the case, the brightness would be controlled by a discrete switch.

My plan was to monitor the PWM input value, and if the PWM input was 100%, then I would go to a predefined brightness. If the PWM input was 0%, then I would go to a different predefined brightness. Any value between 10% and 90%, I would have the brightness of the MD4 set to the PWM value. As I see it now, I am not able to set the PWM input value to read from 0-100%. The default values for these types of inputs are 5-95%, and I can adjust them to cover 1-99%. This would be fine if the input was always a PWM type, but if the vehicle does not have this optional switch, then my PWM value would be 0% or 100%.

Is there anyway that I would be able to accomplish this, without have to make an adjust item?

Customer support service by UserEcho