4-20mA , 0-5,0-10 VDC industrial command signals

4-20mA , 0-5,0-10 VDC industrial command signals

The MC4x now has Current loop inputs (4-20 mA) but no 4-20 mA Output.

Does Parker IQAN ever plan to offer a module (ICP Compatible) with Industrial output command signals Such as 4-20mA , 0-5VDC and 0-10 VDC?

I work with some Hybrid applications that integrate Industrial PLC's with IQAN Mobile controllers.

We are often struggling with signal integration between the two platforms. I know there are CAN to Analog solutions but they cost money and take time to integrate.

Power saving/Idle mode for modules

Power saving/Idle mode for modules

Hello,

It would be nice to be able to set some kind of power saving/idle mode for a module.

Meaning it could be in power saving mode with a very low cycle time and inactivated I/O's, waiting for a trigger event.

In our application this could be used as for e.g. a diesel heater timer. Then we could integrate the diesel heater to the iqan display.

/Fredrik

obsolete hardware database

obsolete hardware database

i see once again on the forum desperate users are chasing around for obsolete parts to maintain existing older systems. We are a Parker distributor and Iqan specialist ourselves and as such have quite a lot of obsolete and/or older hardware on the shelf we no longer specify for our new applications- I imagine there are many others in a similar position with kit lying unused that other users need urgently. How about a forum based database or similar where holders of kit they don't need can upload details, to indicate their unwanted stockholding and potential buyers could offer against?

Modules with more CINs

Modules with more CINs

A lot of new sensors operate on the market operate on 4-20mA. It would be helpful to start expending CINs on all modules.

UL/CSA Listing

UL/CSA Listing

The datasheets do not claim any UL or CSA compliance.

I see other brands of PLCs do.

Having a UL508A control panel is a nice feature.

Any thoughts?

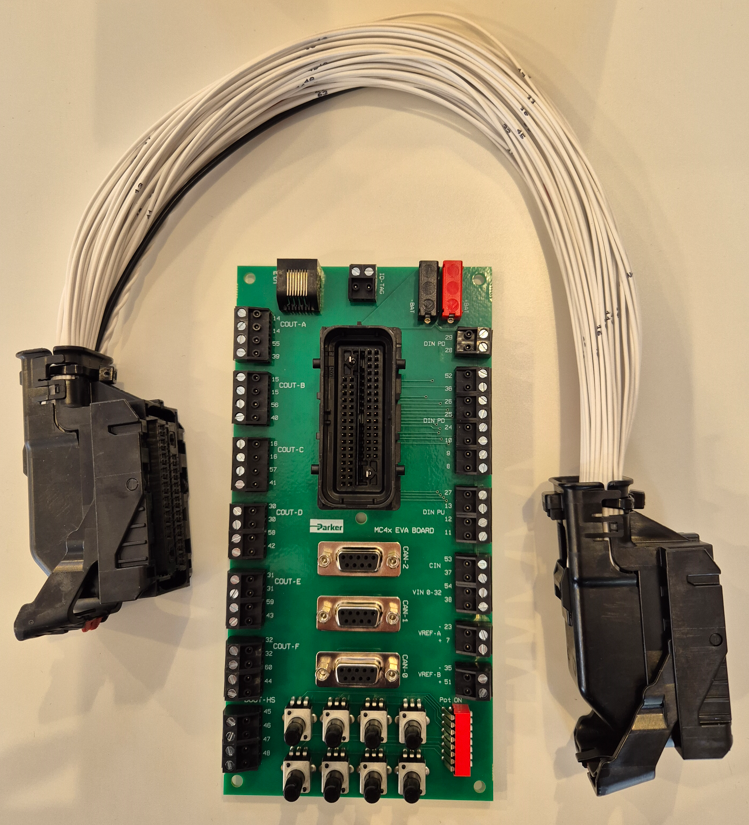

MC4x Evaluation board

An MC4x evaluation board is now available to order, part number 20085169.

This board is meant to be used with all the MC4x units and will connect to C1.

It has all the I/O for C1 connector and can be used for testing everything on MC41 and MC42 and all I/O for C1 on MC43.

The kit includes the board and test cables.

Functional safety for steer by wire

Our colleagues at Parker LORD are running a webinar on functional safety for steer by wire next week:

https://www.lord.com/event/webinar-functional-safety-for-steer-by-wire

Substitute a L90ls electrovalve with resistances:

Substitute a L90ls electrovalve with resistances:

Hello, I want to know if is possible to substitute a L90ls electrovalve with a resistence to check an expansion module.

I want to make a bank to conect a master or a slave module (XP2, XA2, MC43...) and check outputs of the module.

As the electrovalve has 21-23 ohms, I've used a 20 and 30 ohms resistence, but "open load" error appears with both options.

Is there any way to check the outputs with a test bank?

LSL with full Latching/Detent

LSL with full Latching/Detent

Is there any development in an (for example) LSL jostick with full detend/latching

So that the joystick stays in position.

We've had a couple occasions where this would be a great solution.

The IQAN-LSL joystick is available with different detent options, both mechanical and electromagnetic options with different characteristics like detent postions and spring forces. You can read more about them in the datasheet and instruction book.

Datasheet:

Instruction book

module identification

module identification

Marking MC/XC modules

is it possible to mark the modules with the type on the connector side.

if the module is mounted its not possible to see wich one it is

Customer support service by UserEcho