Destination Address

Destination Address

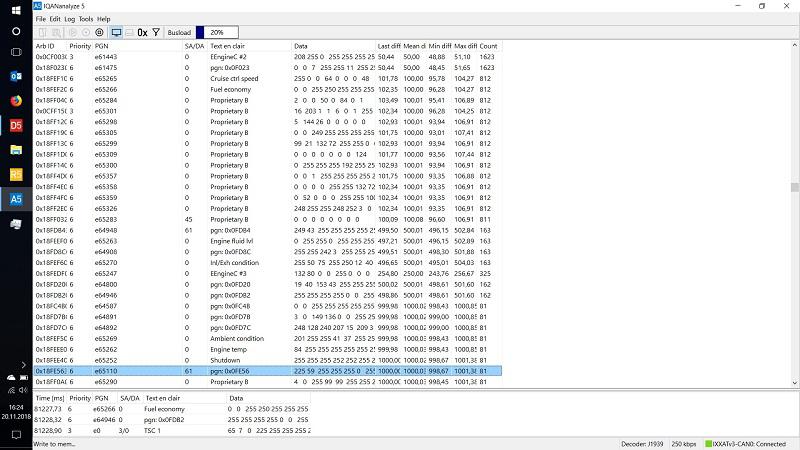

I have the following problem with a J1939 control on a Deutz engine: The PGN 65110 is sent with a Source Address / Destination Address (see screenshot IQAN analyze).

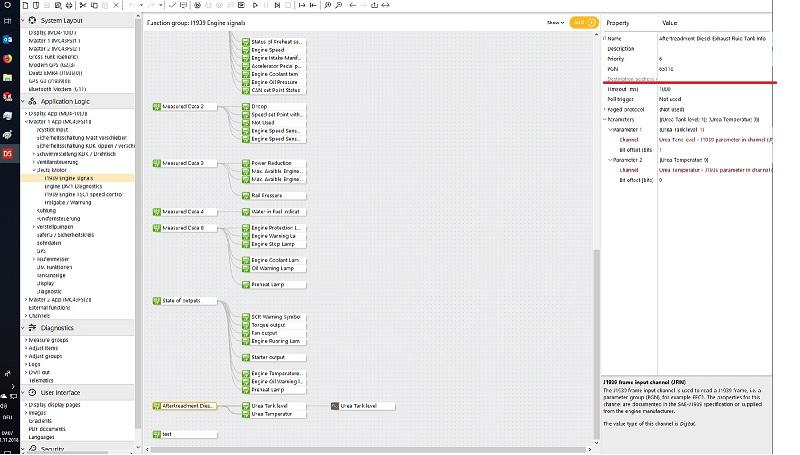

Is it possible in IQANdesign to activate the Destination Address? (see screenshot IQANdesign)

Hello Rainer

In the J1939 protocol, you have different configurations of the 29 bits identifier, where the PGN number is part of.

When the PGN number is between 0 and 61184, the SA and DA are in the identifier.

IQAN analyse will show both.

From 61185 and bigger, we have broadcast messages. In these messages, there is no DA and IQAN will not show the DA.

I hope this helps

Date in Memorizing Channel in 5.04

Date in Memorizing Channel in 5.04

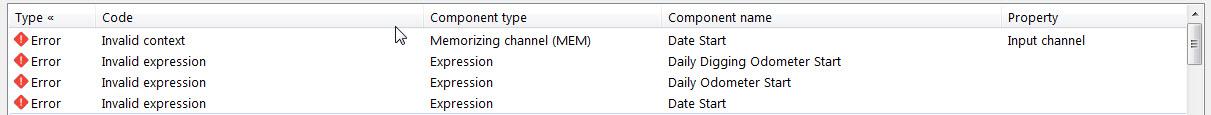

When I updated to IQAN 5.04, I four new errors that popped up that seemed to be related to the fact that it can't use a date data type in the memorizing channel. This exact same program works in IQAN 5.03.

GFIN - add Enable parameter

GFIN - add Enable parameter

Dear could you add a enable parameter on all CanBus function. If we have some option material, it is easy to desactivate some CanBus function.

In generale it could nice to add Enable Parameter on all function.

Regards

Change MD3 address from 0 to 3

Change MD3 address from 0 to 3

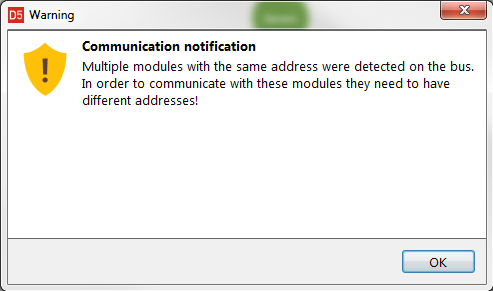

I have 2 x MD3's that previously had been used separately on different machines with an application that had the displays configured as address 0. I now wish to connect them to the same diagnostic bus and install new application software with one as address 0 and the other as address 3. I seem unable to change either of the displays from address 0 to 3. I have the correct ID tags inserted, tried safe mode, tried unplugging one of the displays, tried changing the display (just in case it was faulty), the resistance of the ID tags are correct. Still cant work it out, can anyone help?!

If i unplug one of the displays i can send an application that has a single display configured as address 3, but even with address 3 tag inserted in the rear of the screen it comes up with wrong ID tag on the display. Appears to be the same in IQAN design 3, 4, & 5.

Ethernet communications with MC42

Ethernet communications with MC42

I'm working on my first project using a MC42, our master already has an application loaded.

I'm using design 5, when trying to communicate via Ethernet, my LAN identifies the connection as unidentified.

When I use Get project, no modules are discovered.

Can any one help me with this issue?

Adjust item will not increase above 99999.99

Adjust item will not increase above 99999.99

I have a memory channel with a range of 0 to 9,999,999. I have it in an adjust group with a step size of 1608. (The channel is meters and 1608 is 1 mile.) When using the adjust tool in runtime, the tool will not allow the value to increase above 99999.99.

Default values in multi state function parameters

Default values in multi state function parameters

I am working on a program that is for multiple machines with multiple different default values. We currently use a FP with a run mode that has multiple states to create default values for each state. The issue I have is where each machine has different defaults I have to duplicate this for each machine.

It would be nice if the Default Values could be dynamically changed. I have a few different workarounds, but this seems like a simple request that I am sure others have run into?

CANOpen 11bit and 29bit ID on same bus?

CANOpen 11bit and 29bit ID on same bus?

Can CANOpen 11bit and 29bit ID on same generic bus?

you have to add a second generic bus on the same port and set it to 11 bit.

Software License Key for Design 5 - backwards compatible for creative studio 4, 3,2?

Software License Key for Design 5 - backwards compatible for creative studio 4, 3,2?

If a customer purchases a license for Design 5 (only, not developer suite), should the license key work for creative studio 4, 3, 2?

He needs Design functionality in old programs as well.

Lost message on master bus ?

Lost message on master bus ?

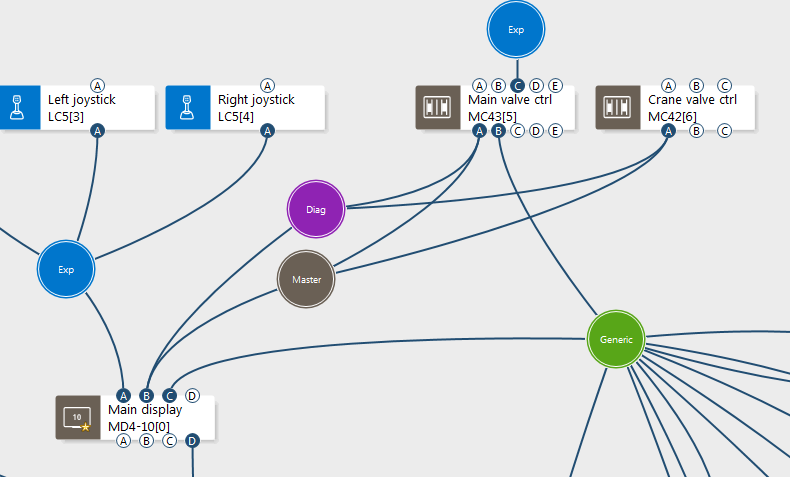

We have 3 master modules connected according to image above...

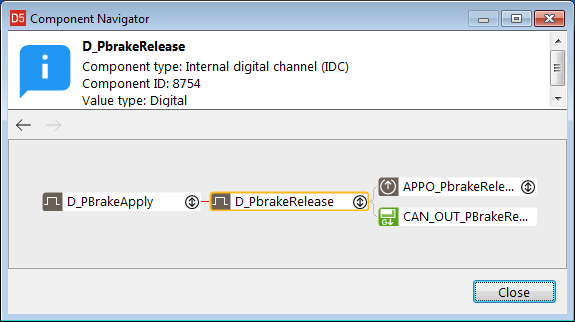

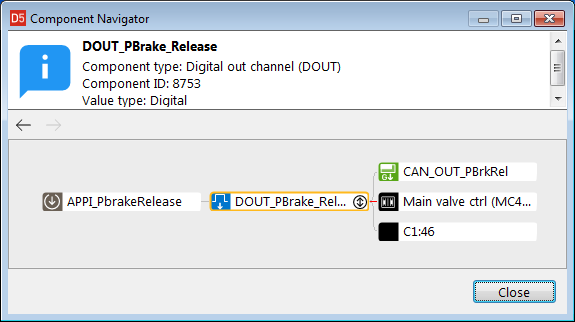

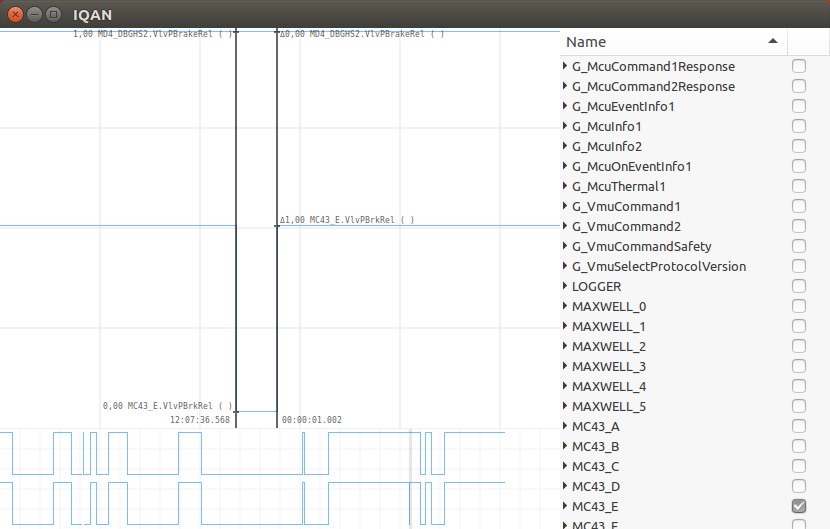

We send a P-brake apply command according to the image above. One goes out through the APPO_PbrakeRelease channel supposedly through the "Master" CAN-connection. The other goes out as a Generic CAN-signal through the "Generic" CAN-connection...

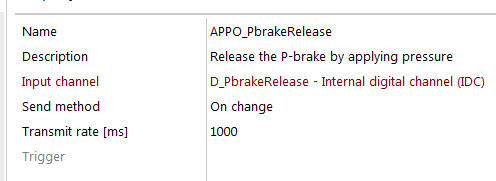

The APPO_PbrakeRelease channel is configured as shown in the image above. 1s transmission rate or on change.

On the receiving side, the input is controlling a digital output. The value of this digital output is also transmitted on the "Generic" bus. In other words, on the "Generic" bus we can see the value that should be sent out through the APPO_PbrakeRelease channel as well as the value that is received on the APPO_PbrakeRelease channel...

The problem is, occasionally we see a glitch as the one above. The value that is sent is constantly HIGH, while the value received goes low for exactly 1s and then goes high again. We have seen this for other digital "Application OUTPUT/INPUT" channels as well.

The fact that the time (1s) perfectly matches the outgoing transmission rate configured at the sender leads to the conclusions that one CAN transmission is corrupted and that the following transmission, 1s later, is correct and again sets the correct value. If it had been an actual change of the input signal, then I assume the APPO_PbrakeRelease signal would have been sent again as soon as the input changed back again?

Also, that the "Generic" CAN-transmissions which has a transmission rate of 20ms, doesn't show any incorrect values limits the error to the "Master" bus only. We have so far not seen any similar behavior on the "Generic" bus.

The "Generic" bus is connected to CAN-bus logging device that records every CAN-bus message transmitted without any filtering or "sampling interval". So, if we can't see any change of the signal here, then no such signal has been sent on the bus.

Is it a known problem "Application OUTPUT/INPUT" signals can get corrupted? And more importantly, how does one handle this?

Customer support service by UserEcho