How to get the MEM with Store Value via IqanScript

How to get the MEM with Store Value via IqanScript

Hello,

Is it possible to get the value from a MEM channel with Store value = yes via Iqanscript?

We need to read this value for the porting between MD4 to MD5.

Thank you in advance

Shutdown Sequence when uploading code

Shutdown Sequence when uploading code

Our machine needs to go through a few steps in order to shutdown properly. With this, our machine throws errors when we try to upload IQAN code as certain components do not get any warning they are about to be shut down.

I was wondering if there was a way to get a signal to begin the shutdown sequence when uploading code such that these components can go through their normal motions before power is cut off.

How can I transfer the license key for iQANRun7? How to remove the license from my device?

How can I transfer the license key for iQANRun7? How to remove the license from my device?

Could you please clarify how the IQANRun 7 license works?

-

Is multiple installation allowed under a single license?

-

In what situations can a license conflict occur?

How to transfer the license key between devices?

Ho to deactivate the license? i don't see license manager.

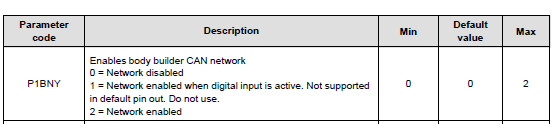

Can bus communication J1939

Can bus communication J1939

I'm pretty new to J1939 communication and need a little guidance how to send "codes" to a truck. To read on bus traffic (parameter in/frame in) i have learned the hard way, but now i need to send also. For example how do i send this code? Which "boxes" should i use? If someone explains this, then i think i will figure out the rest on my own :)

Is the softing CAN card supported by IQANRun7?

Is the softing CAN card supported by IQANRun7?

Is the Softing CAN USB adapter supported by IQANRun7?

Scrolling in User Interface

Scrolling in User Interface

Hello,

We are experiencing a user interface issue in Iqan Design 7.05.19.10562.

When editing a page on the display and scrolling in the Layers panel (for example towards the bottom), the main screen keeps scrolling along with it.

Even though the mouse cursor is positioned in the layer navigator, the display view continues to move.

This makes working quite difficult. Ideally, the scroll action should only affect the area where the mouse cursor is located, and the display view should remain in its current position.

Has anyone encountered this behavior before, or is there a setting to prevent the screen from scrolling together with the layer panel?

Thanks.

IQanrun 7 instalation location

IQanrun 7 instalation location

Hi,

I see the topic about IQanrun installation , but wondering if anyone find a way to change the instalation location. We are using 4x shared laptop and like 20 people use it. I dont want to reach everyone 4 time. Will take forever to do.

thank you

Dynamic range for slider control

Dynamic range for slider control

I like to use the Slider control in my project, as per the requirement the slider min and max value should get updated based on selection (that will be a CAN signal), Now the issue i am facing is the slider is showing fix min and max value .The max value is used from the GPOUT signal which is Fixed .

Text formatting channel padding

Text formatting channel padding

There should be a way to set fields in the Text Formatting Channel to have padding with leading 0s. E.g. If set to be padded to 3 digits then 5 would be printed as "005". This is effectively the "Number of Decimals" filed, but in the other direction.

An application would be for a clock formatted string (e.g. for countdowns). currently, 0 hours, 5 minutes, 17 seconds would print as "0:5:7" instead of the desired "00:05:07".

For searching, this may be referred to as Padding, Leading Zeros, Leading 0s, Fixed Length Numbers, Number of Digits, or Significance.

Wireless can bus

Wireless can bus

Has anyone tried this between Iqan masters, like MD5 <-> MC42?https://www.ifm.com/fi/en/shared/productnews/2023/hmi/canwireless-effective-local-m2m-dialogue

Or is there some other wireless CAN-bus adapter that works in Iqan?

Customer support service by UserEcho