IQANRun does not execute the script if executing from command line

IQANRun does not execute the script if executing from command line

I am evaluating IQAN and am using the Fine Control example project with a simulator. I am trying to run an IQANscript script to fetch the logs from the simulator. Running the script works if I manually select it from the IQANrun user interface but when I run it on command line interface

.\IQANrun.exe -cif Simulator -send "Path\To\Script.issx"

The software will start and connect to the simulator but will not execute the script. I was wondering if this is caused by the evaluation version or are the command line interface parameters incorrect?

SW versions

ICANdesign 7.00.45.8646

ICANscript 7.00.25.6507

ICANrun 7.00.54.6971

ICANsimulate 7.00.27.6511

IQAN Simulate

IQAN Simulate

Hello,

Is it intentional that I can't customize items in IQAN Simulate? I don't have a module to try out the application on hardware.

I can't find any explanation in the documentation.

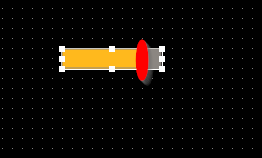

Linear Bar Image

Linear Bar Image

Is it possible to add an image or indicator to the linear bar? I would like to put a dot on the end of the sliding bar for better visibility. for example, in the image below I would like that red ellipse to move with the end of the bar.

Copy and paste text item on display screen results in crash

Copy and paste text item on display screen results in crash

IQAN 7.0.

Multiple text items on screen, some single line and some multi line. When copy and paste some text box items, design does not crash, but others results in crash. Its not random, always seems to crash on the same text copied shown in video.

I have noticed as well I get crashing when copy and pasting the grey lines in some instances so appears not just isolated to text boxes.

No crash report generated, design window just freezes and closes. No windows error, but on load up on IQAN Design again I get locked file notification.

Will send the video using 'send a file'.

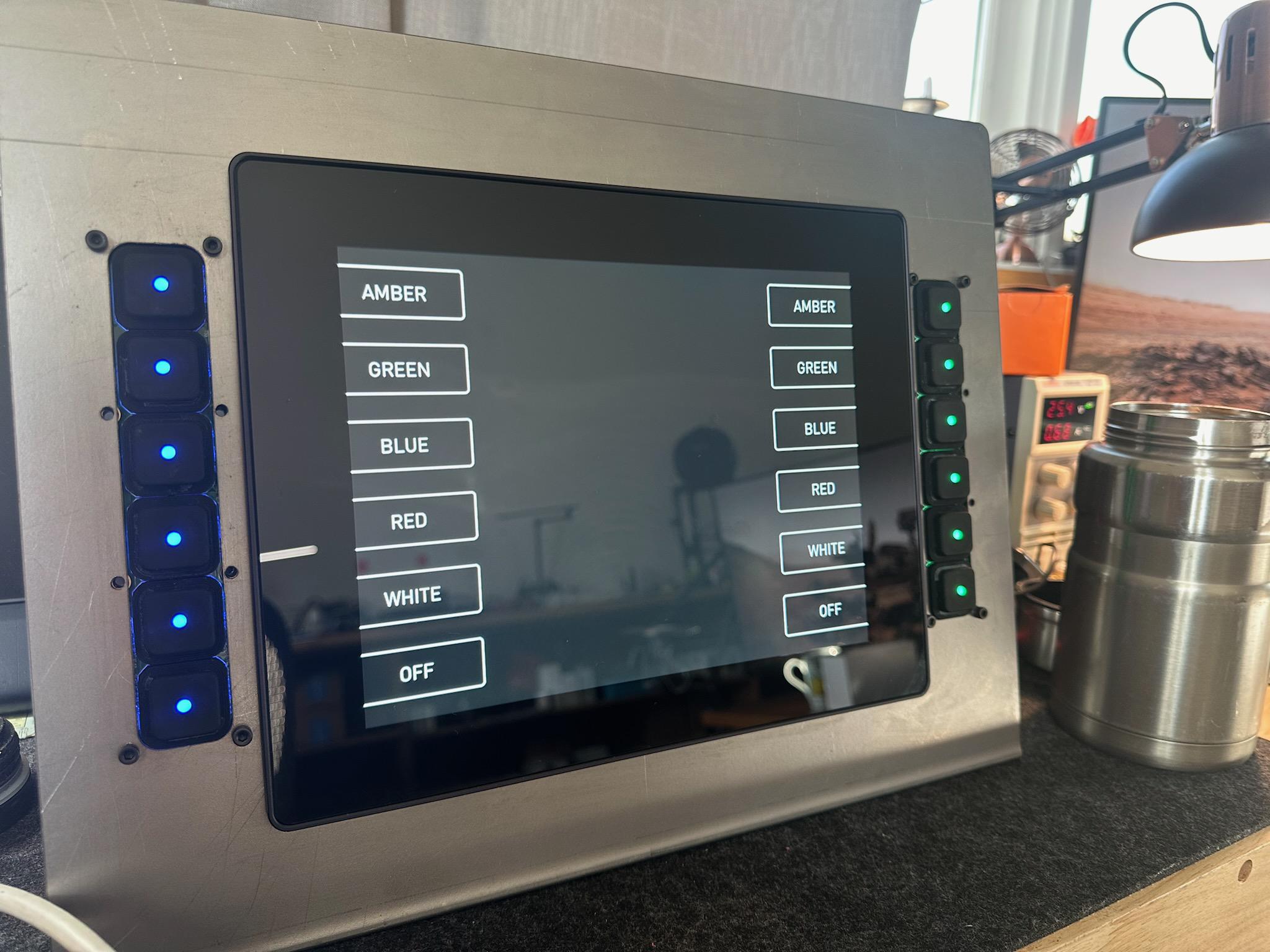

Activating channel for the VDINs

Activating channel for the VDINs

Hi Gustav

I am currently working on a project where the operators must wear gloves. Since making any touch interactions would require gloves to be off I implemented side J1939 bezel keys. What would be super helpful is if the VDINs could have an activating channel added such that if the side button is pressed, touch button would respond accordingly.

No sure if there any any way this can be done now.

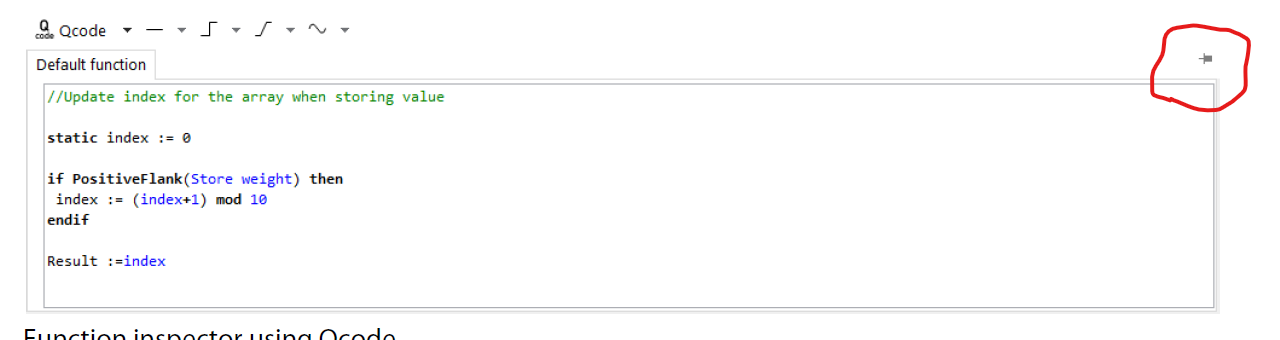

Function inspector Design 7

Function inspector Design 7

In Design 7 I'm missing the pin function on the function inspector window.

Will this be added again in a future update?

It is a bit annoing, that when working on the bottom of the page, every time it pups up again it overlaps the bottom of the page and you need to scroll down to see the part that you are working on

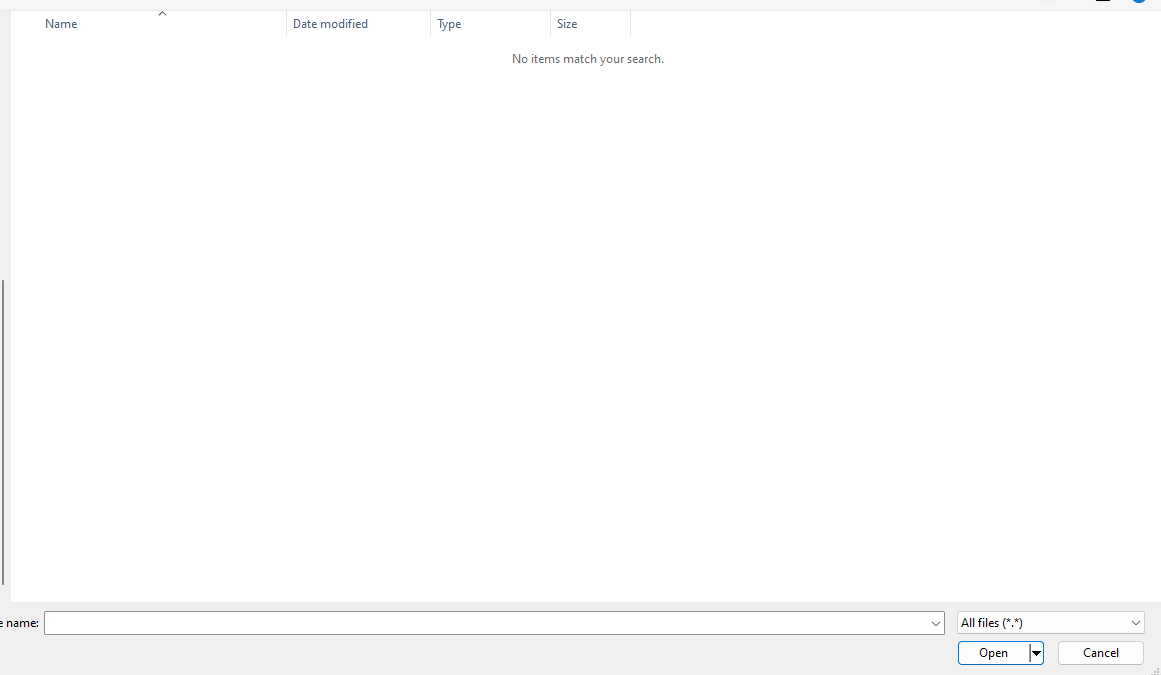

Opening project in IQAN Design, windows filter 'ALL' does not work

Opening project in IQAN Design, windows filter 'ALL' does not work

Opening existing project in IQAN Design 7.0 then select 'ALL FILES', does not show items except folders. Other filters such as clone and project file seems OK. Tried on 2 computers and seems to be the same on both, possibly a bug.

In this folder above is a clone and project file.

Resize channels

Resize channels

Once resized single or multi channel, it is not possible to return to original size,

only able to return to original size + appr. 2 grids

Is this normal ?

No Issue with function groups

Heap check failed

Heap check failed

Hello,

What is a 'Heap Check Failed' error, and could it be related to slow navigation between screens?

I am also seeing 'Error Initializing embsup.dll' in the Project Statistics. Wondering if that is related.

I am getting the error on a MD4-10, using IQAN 5.07.1.2473 (though I inherited this project, it may have originated in an earlier version).

Project is about 11MB.

I see there is another post about this here. Not sure what the solution was though.

Would simply upgrading to Version 6 resolve this, and would that potentially resolve the slow screen issue.

Also I have no issues Simulating the project. When the app is loaded to an MD4 it loads fine, however it navigates between screens very slow.

Array in Initialization

Array in Initialization

Would be nice to be able to using an Array in Initialization.

I'm currently storing Screen ID's in an array, this array doesn't change so would be nice to initialize it, and not have it calculating each cycle.

I'll likely post a second idea about this, but on the topic of Arrays, would be nice to be able to store text in a Array.

Customer support service by UserEcho