Error during startup on XC44

Error during startup on XC44

Good afternoon,

I have a system that uses an MD4-5 as the master and several XCx modules as extension módules. One of the XC44 modules randomly fails to connect when I power up the system, and the LEDs indicate the following error:

"R4:3 3:1:7 Startup check. Expected after update of XC4x to FS capable version."

This error is random; it may not appear for a week or it may appear several times on the same day.

I have checked the wiring and it is correct, as is the battery voltage.

Telematics

Telematics

Telematics signal ID 19 data type real is showing up in our modem data stream as 0 when program is on a functioning machine. If the program is on our test bench that does not have any I/O, the value is exactly the value we would expect it to be. We have done lots of testing to narrow down the root cause. Our best understanding right now is that when the program is running on a real machine, the I/O is changing values. That seems to be the difference between the test bench and a real machine. Some of those I/O values are sent to display page items over the DIAG CAN from an MC43FS address tag of 0 to a display address tag 1. If we set up the display to never show a page on a real machine, signal ID 19 is the exact value we would expect it to be. Is this a known issue or has anyone else experienced something like this? We are using IQAN design 7.04.8.10088. We have also used IQAN design 7.05. The issue still exists.

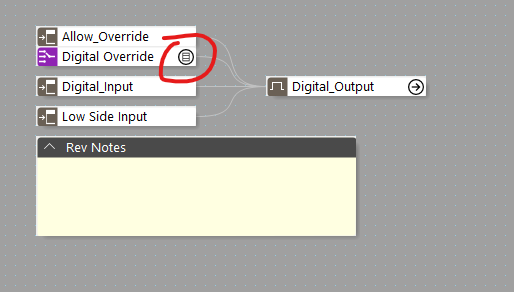

Coping an external function removes adjustable item

Coping an external function removes adjustable item

When you copy and past an external function it will remove

Insert an external function (everything is correct)

I copy and paste it, to and another one. And the ability to now adjust this item is removed, and I cant not figure out any way to fix this. Other then deleting the whole group and adding it manually back.

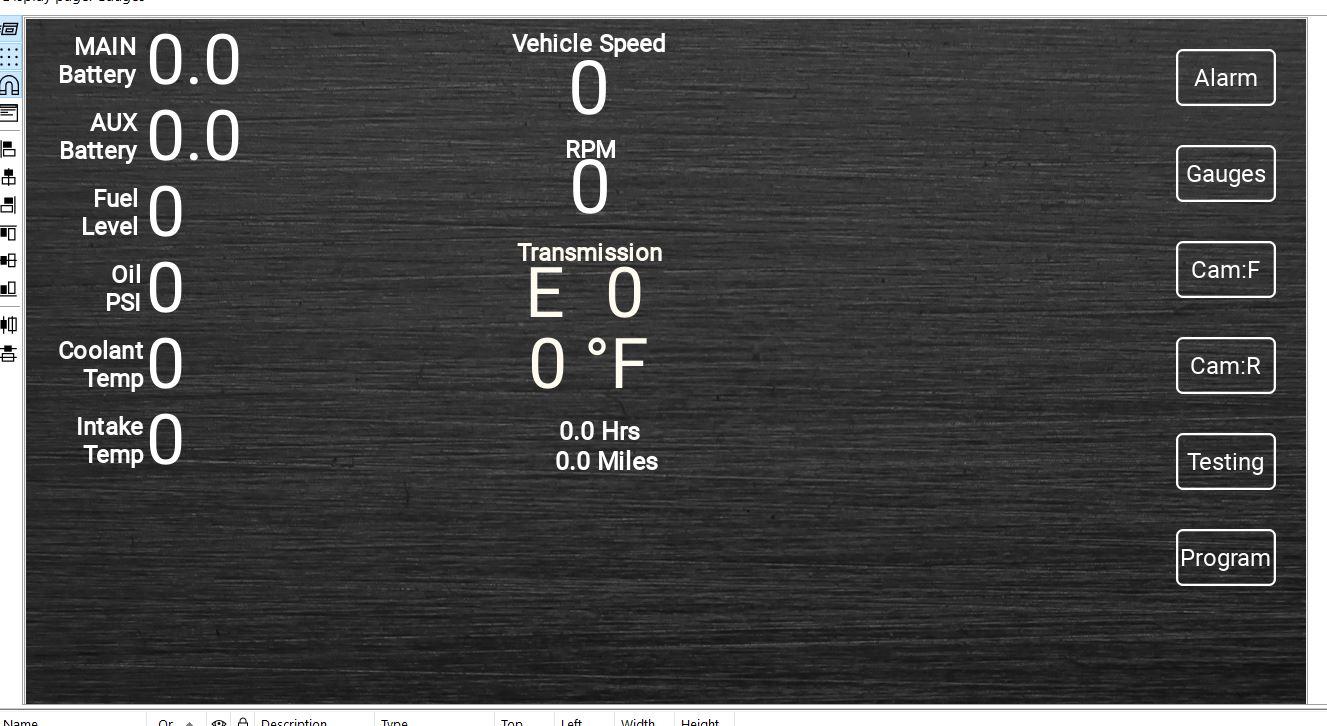

Display Objects not updating position (Layer Issue)

Display Objects not updating position (Layer Issue)

Running the latest version of IQAN 7.05.27.10981, I am having a problem where buttons will not update location on simulate and the physical display.

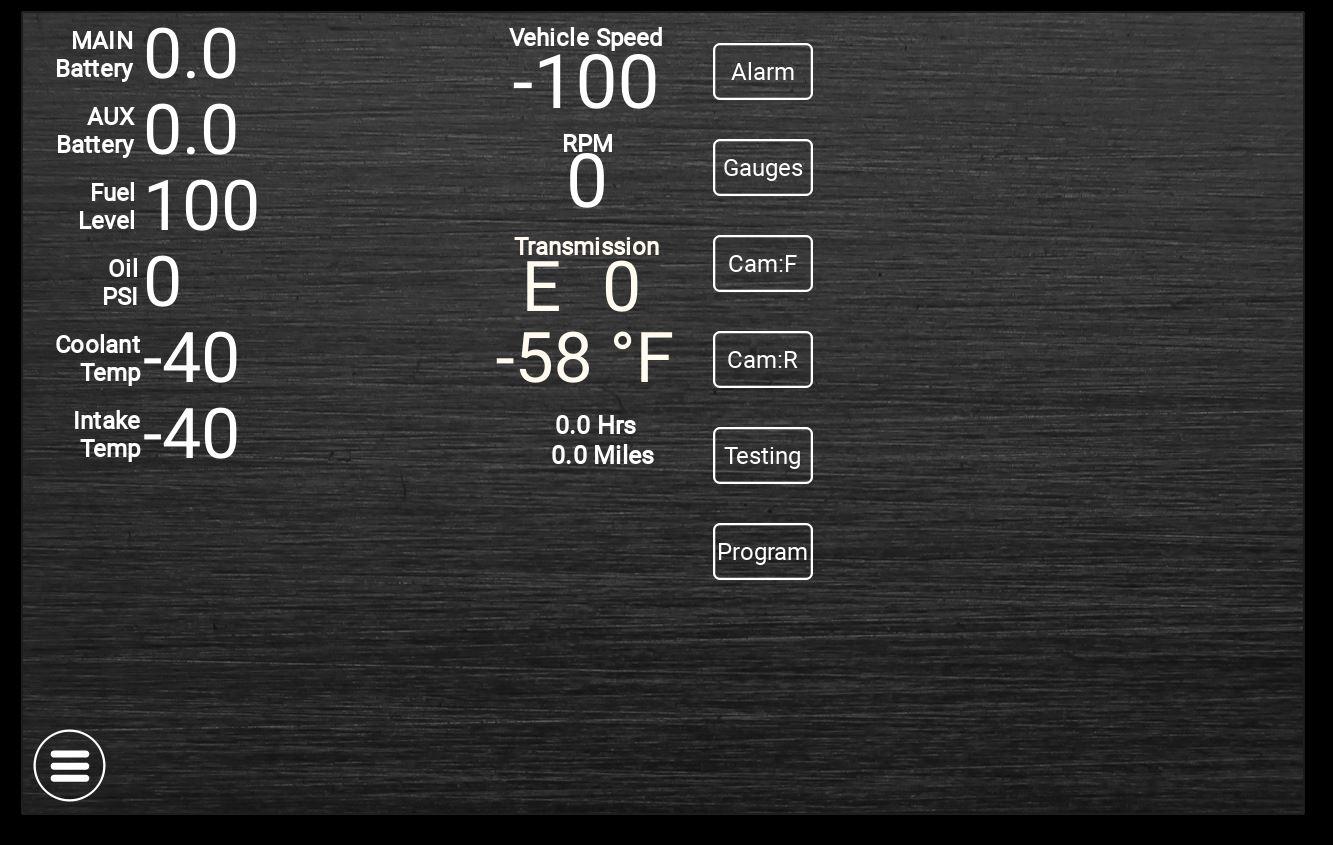

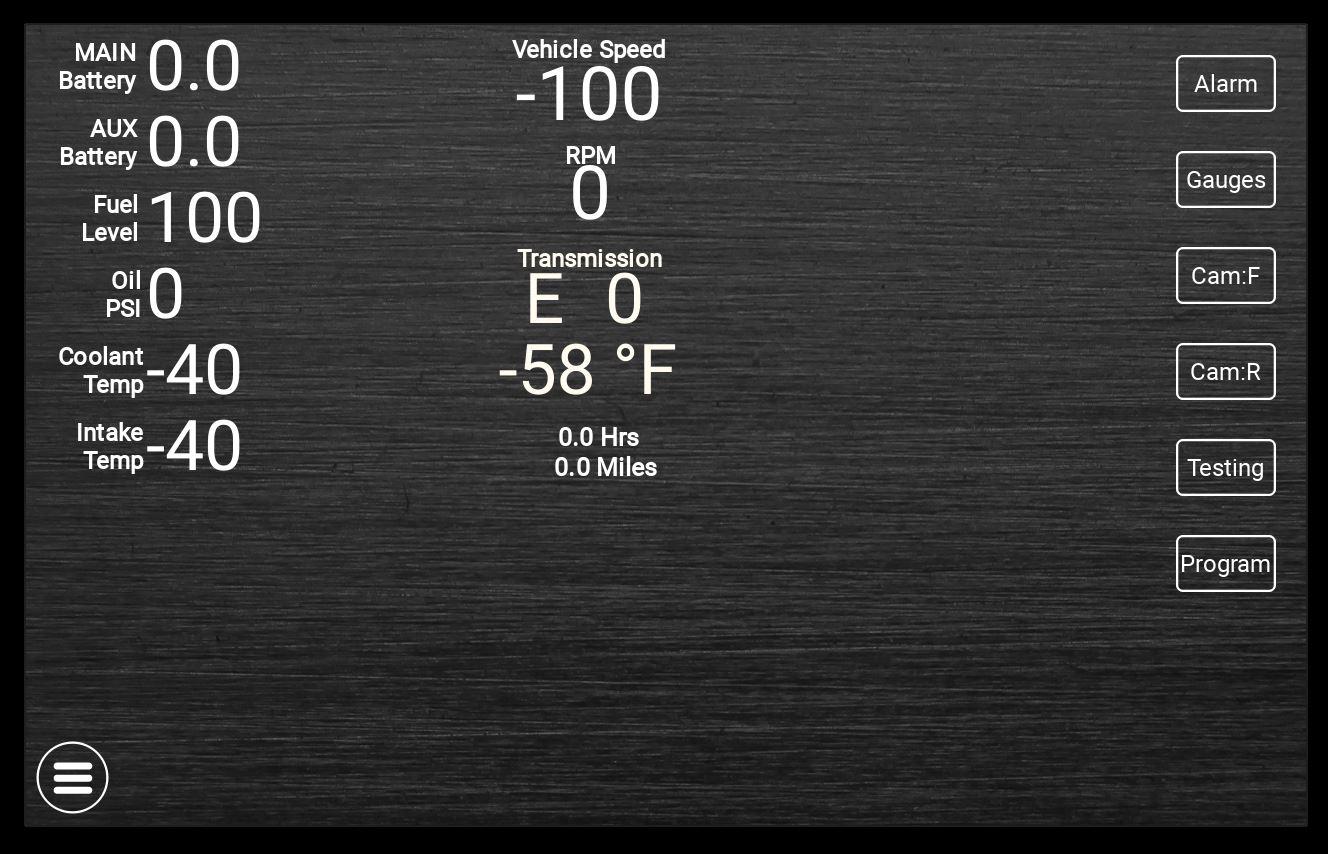

In design it looks like this.

Simulate and if I program the display it looks like this.

If I delete the layer these items are on and add them to a new layer then everything is fixed.

Undefined SPN DM1 warning message box: confusion caused by only last active SPN/FMI shown as faults go inactive

Undefined SPN DM1 warning message box: confusion caused by only last active SPN/FMI shown as faults go inactive

I would like to see the behavior of the DM1 fault message popup change with regards to how it updates when faults go inactive. Currently when there are multiple undefined SPNs active, and they all go inactive, all but the last active fault is left displayed in the warning message. I will provide an example below where an end user might be able to solve the problem by sending a picture to their dealer, but the current way the dialog works might result in a dealer service call. Could we perhaps have a way of still showing these faults on the DM1 warning popup, but indicating that they have gone inactive? Perhaps put an “IN” on the line with the SPN/FMI that is inactive?

EXAMPLE Case:

SPN/FMIs active for:

- DEF quality. (Bubbles have accumulated on the sensor after filling causing a temporary unstable reading.)

- SCR fault caused by elevated NOx. (Since the dosing system has stopped dosing because of the previous fault.)

- 1st torque derate fault (due to emissions issue being present for a given length of time.)

The machine has been running for some time, but the DEF quality fault is not reassessed until a new key cycle. Once the first torque derate kicks in the operator shuts the machine off and restarts it to see if the faults go away. Given that it hasn’t, he leaves the machine to grab his supervisor who calls over the maintenance team. Since he has left the machine running, the DEF quality fault clears and now only the elevated NOx and 1st torque derate message are left. By the time the maintenance person gets to the machine, all faults have gone inactive, but only the 1st torque derate is still shown.

The maintenance person takes a picture of the main screen with the DM1 warning showing only the SPN/FMI combination for the 1st torque derate and sends it to the dealer’s service team to see if there is any way he can fix this without a call out, as this is a recurring but sporadic issue. He hasn’t found the correlation between one of the DEF pumps on site pumping faster causing aeration of the DEF when refilling the machines.

Because there are many different types of problems that could cause a torque derate, the dealer sends out a tech with the engine diagnostic tools. Had the dealer had the DEF quality SPN/FMI they could have passed along a service bulletin from the engine manufacturer that relates to aeration causing these fault codes, and the end user could have verified this as the cause and implemented countermeasures such as lower flow DEF pumps at their fuel depot.

MD5 running 7.03 turns blank during update

MD5 running 7.03 turns blank during update

We have recently found a big problem when attempting to update an MD5 screens over CANbus or G12’s.

The firmware will start to send and get roughly 30% complete before the screen goes blank and dark.

Design shows to still be sending the file but the screen is unresponsive. You can power cycle after this crash and it will show no program message.

The only way to fix this seems to be with Ethernet connection. We have had 3 Md5’s now with this same issue and becoming a major problem, as several customers have relied on G12 update support on the field.

Undefined SPN DM1 warning message box: confusion around more than 3 faults.

Undefined SPN DM1 warning message box: confusion around more than 3 faults.

In the current iteration of the iQAN software, when a dialog for undefined DM1 SPNs appears on the MD4, it is limited to only showing 3 SPM/FMI values. If there are any more, at the end of the last shown FMI it will display "...".

Techs in the field who are doing an initial assessment on a machine tend to not understand that there are more faults active, that they can't see without going to the module status page in the system menu. Could we perhaps get a "more" button they can press to directly open this page when more than 3 faults are present?

Propagating Inputs

Propagating Inputs

Hello,

I find the Propagate Outputs feature to be extremely useful. It would be beneficial to allow function group inputs to be propagated as well. I tend to use nested function groups quite often to keep my programs clean and easy to follow, and as a result I will typically have the same function group input repeated in order to pass information along. This feature would not be useful if that data being passed through each function group was being used in each one, but I often find myself passing data through function groups without using it in any of the intermediate function groups. For these cases, being able to propagate inputs would be extremely helpful.

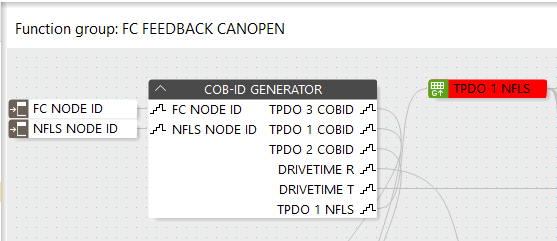

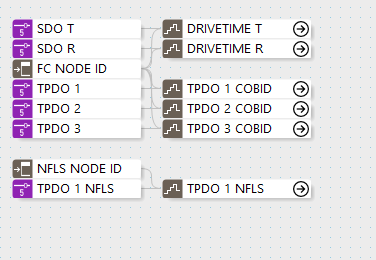

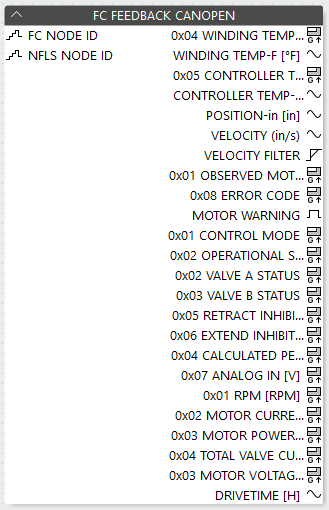

The below example should help clarify what I mean. This is a part of an external function I am creating to control a CANOpen device. To make this external function as generic as possible, I have created this COB-ID generator module that will combine a user defined Node ID with a predefined TPDO/RPDO. This nested function group is the only part of the program that interacts with the FC NODE ID & NFLS NODE ID function group inputs. These FGIs would not need to be in place if propagating inputs was implemented. The middle picture shows what is inside the COB-ID GENERATOR function group, and the last picture shows the main external function group.

Cannot simulate some variants option in project

Cannot simulate some variants option in project

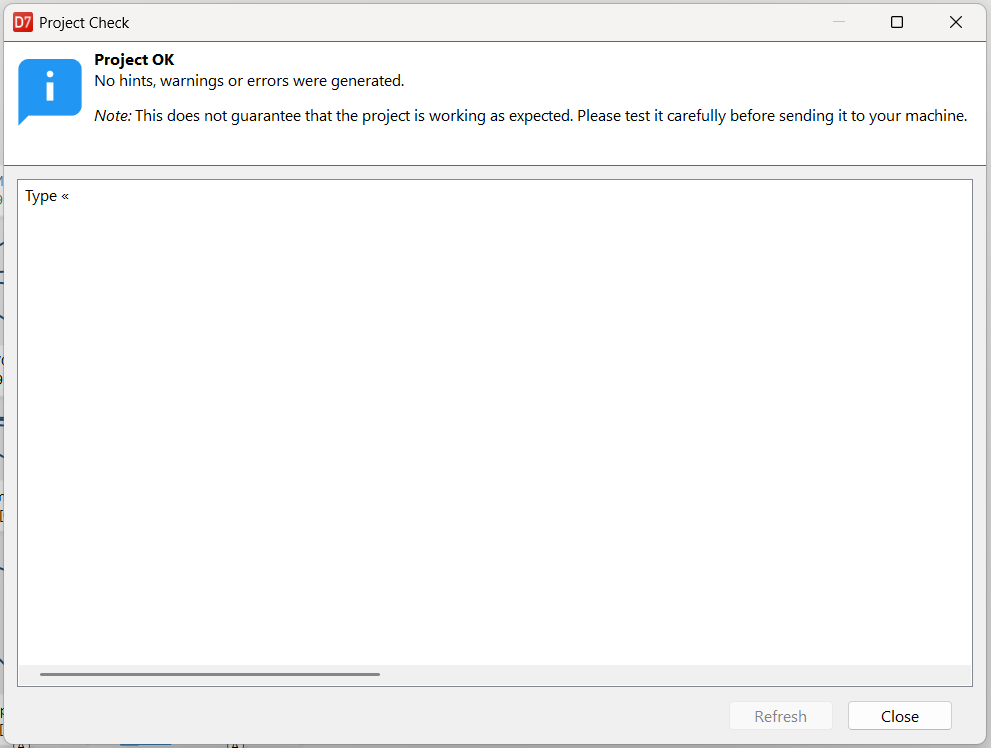

I am working on a project with four variants. When I click the Run button in IqanDesign, the simulator only works on one of them.

On the other variants, when I click Run, it checks the project and the following window appears, making it impossible to continue:

Variant Source address adjust

Variant Source address adjust

Hello, I have a engine control project that I use the same base program but I swap from a Diesel engine to Natural gas. The Diesel uses Source address 0 and the Natural Gas uses 39. I have a MD4 and MC43FS. I have variant programs as it changes they control function between the Diesel and the Gas. That works good but i have to manually change the source address each time I upload. It would be good if we could in the initialization use a variant that would select the appropriate source address. Maybe there is already another way to do this? Or if we could set some CAN messages to accept from any source address.

Customer support service by UserEcho