Simulink Model in IQAN MD4-7 Module

Simulink Model in IQAN MD4-7 Module

Hello,

Is it possible to load in compiled simulink models into IQANdesign configured to flash onto an MD4-7 module? Thanks.

CAN routing with modifications

CAN routing with modifications

Hi all,

Is there a simple way to do CAN routing from one channel to another using the CAN routing option where we block one incoming PGN on the. IN BUS, then with a JIFIN etc, read the same PGN coming in, and modify 1 BYTE and send it to the OUT BUS with a JIFOUT. Rather than adding every PGN to and passing them through etc?

IQANdesign 7 not able to program using Bluetooth

IQANdesign 7 not able to program using Bluetooth

Hello, I just updated from Version 6 to Version 7 and cannot send or receive programs through Bluetooth.

Setup:

Modules: MC43 / G12.

IQAN Design Version: 7.00.45

Issue:

Using IQAN Design through Bluetooth, I can connect to the G12 and see the diagnostics when selecting start measure. But it will freeze when selecting stop measure.

After attempting to select Send or Received, IQAN Design goes to "not responding" and freezes.

It does the same when trying to update the "Set Date and Time" only through IQAN design.

We have 2 other team members with the same issues.

I have no issues using Version 6.

Iqanrun6 and 7 Password request to upload new project file

Iqanrun6 and 7 Password request to upload new project file

trying to upload a parameter change file from factory to a module. I click send file using version 7 or new project using version 6. Both prompt for password as soon as I select file. I have another technician using same process and no prompt for password. There shouldn't be a password.

IQANrun license/internet issue

IQANrun license/internet issue

I am failing to Connect to IQANconnect Server when trying to connect to remote. I have full internet access and can browse web pages correctly, but it appears the license cannot pull correctly. Internet Connection is working and no proxy is required.

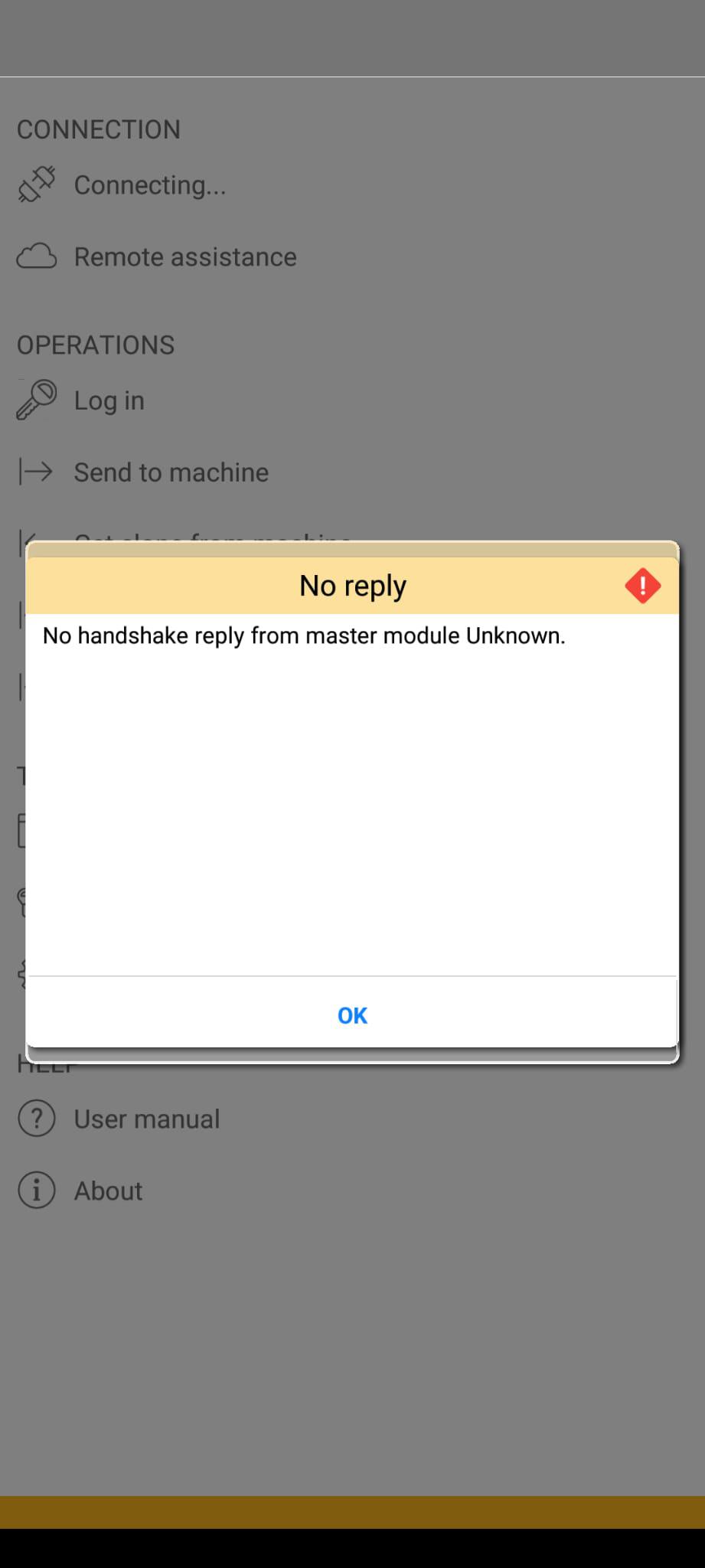

IQANgo 7.00 for Android fails to connect via internet

IQANgo 7.00 for Android fails to connect via internet

We are using iqan connect for quite some years already.

But yesterday we got the update on our android devices to iqango 7.00.38

we connect remotely to G11 modems with firmware 1.12.2.1722.

So far that works, but for some reason a connection to the MC43 master is not possible which has a project built with IQAN design 6.08.22.8040 (older versions also don't seem to work).

This worked perfectly before we got the update, unfortunaly we cannot undo the update as our phones all updated themselfs.

We are in the middle of harvest and already had a dozen of customers which we cannot help properly because we cannot login to their machines.

The connection over bluetooth over iqango or iqan design without iqan connect in between works like it always did, but the remote connection just doesn't.

the message as can be seen below shows up for ourselfs, and that's it.

Move Function Group Around Under 'Application Logic'

Move Function Group Around Under 'Application Logic'

I have added function groups in the tree on the left hand side in the wrong order and it seems you cannot move them around. Operationally it has no effect, but to please the eye ideally I want to have Start/Heartbeat to the top and have slew and boom underneath. I cant seem to find a way of doing it aside from deleting or renaming them and transferring the contents? May be missing something but if not, can we have a feature added to move them around by drag and drop please?

Cant extract clone from iqan run 2, with windows 10

Cant extract clone from iqan run 2, with windows 10

Hi, i cant extract clone from mdl-1 or mdl-2 unit with iqan run 2 under windows 10. I know that other persons on my company has the exact same issue. But if i use same iqan run 2 software with windows 7 it worx. Any ideas on how to solve this? by the way i can extract settings but not clone. In the middle of the extraction process (in win 10) i get connection lost.

/Daniel

DM1 Out with Occurance

DM1 Out with Occurance

I want to use the DM1 Out function which is very helpfull for my project. So thanks! But can I also send the Occurance with the DM1 message?

Can you also use UNsigned integers in iQanDesign?

Can you also use UNsigned integers in iQanDesign?

I want to use a 32 bit UNSIGNED integer. I don't see how I can change the signed integer to unsigned. Is this possible?

Customer support service by UserEcho