Swapping MD4 Displays

Swapping MD4 Displays

Does anyone know how to "easily" change master displays in an application without having to rewrite the whole application? I wrote a program using an MD4-5 and one of my peers would like to see the same program in the larger MD4-7 display.

4-20ma

4-20ma

I am looking to control a 4-20ma device from and MC43, and I was curious if anyone has done this with the current outputs using a max range of 20ma? It is just such a small part of the range I was curious if anyone has had issues, or have done it.

Way of extracting display message contents?

Way of extracting display message contents?

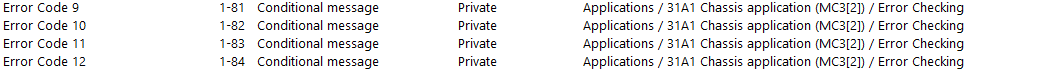

Our customers like how we have used display messages to show error codes on screen. They also like to have them in machine manuals for reference if ever required. To get them in a manual someone has to go through each individual fault code and copy and paste out of IQAN Design into a excel document. Is it possible (or can it be added) for IQAN Design to export all message data to a excel file or CSV or similar to save us manual copy and paste? Perhaps place them in a table so its easy to extract name, header and text detail to be placed in a document such as a manual? Its very boring work, especially if you have lots of error codes like our machines have!

CANopen and IQAN GFOUT/GFIN identifier

CANopen and IQAN GFOUT/GFIN identifier

What is the Gfout identifier value?

Background: Have used the norgren vs18 canopen pneumatic valve for years. Identifier was 200hex+nodeid.

Have to switch to the metalwork Eb80 pneumatic valve. Metalwork provide a EDS configuration file which is not supported by iqan. How do you find the direct canopen identifier to use?

Any hints?

J1939 Source adress from integer

J1939 Source adress from integer

It seems that it is not possible to link a math integer or integer paremeter as J1939 source adress in external function....

Max number of paged parameters?

Max number of paged parameters?

Im having issues with some muxed j1939 parameters. I have seven sets of values that are using the paged protocol on the same PGN. What I'm finding is that i have a few of the PGN'S coming in correctly then if i make changes the ones that previously worked will quit working and the others will work. Is there a limit to what the Iqan MD4 or MC43 can handle? PGN is 65534 and page values are 79,77,90,7A,F7,F8,81. Im using a 0xFF page mask. Send times are as low as 10ms and as long as 200ms.

Hello, I'm new to IQAN, where can I get solution library folder to look for IQAN program examples. I'm trying CAN communication between two MC43's but when simulating it using IQAN simulate I cannot see signal sent on JFOUT in JFIN, please help me with eg

Hello, I'm new to IQAN, where can I get solution library folder to look for IQAN program examples. I'm trying CAN communication between two MC43's but when simulating it using IQAN simulate I cannot see signal sent on JFOUT in JFIN, please help me with eg

Hello, I'm new to IQAN, where can I get solution library folder to look for IQAN program examples. I'm trying CAN communication between two MC43's but when simulating it using IQAN simulate I cannot see signal sent on JFOUT in JFIN, please help me with eg

Show log from MC42 on MD4 display

Show log from MC42 on MD4 display

Is it possible to show a log from a Module MC42 on a display module MD4?

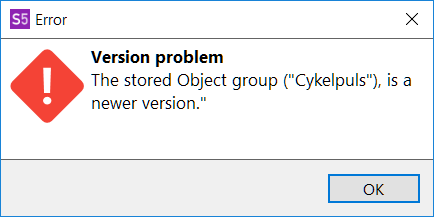

simulator Version problem.

simulator Version problem.

When trying to start a simulation i get the following error.

What could be wrong?

I choose 'New simulation'.

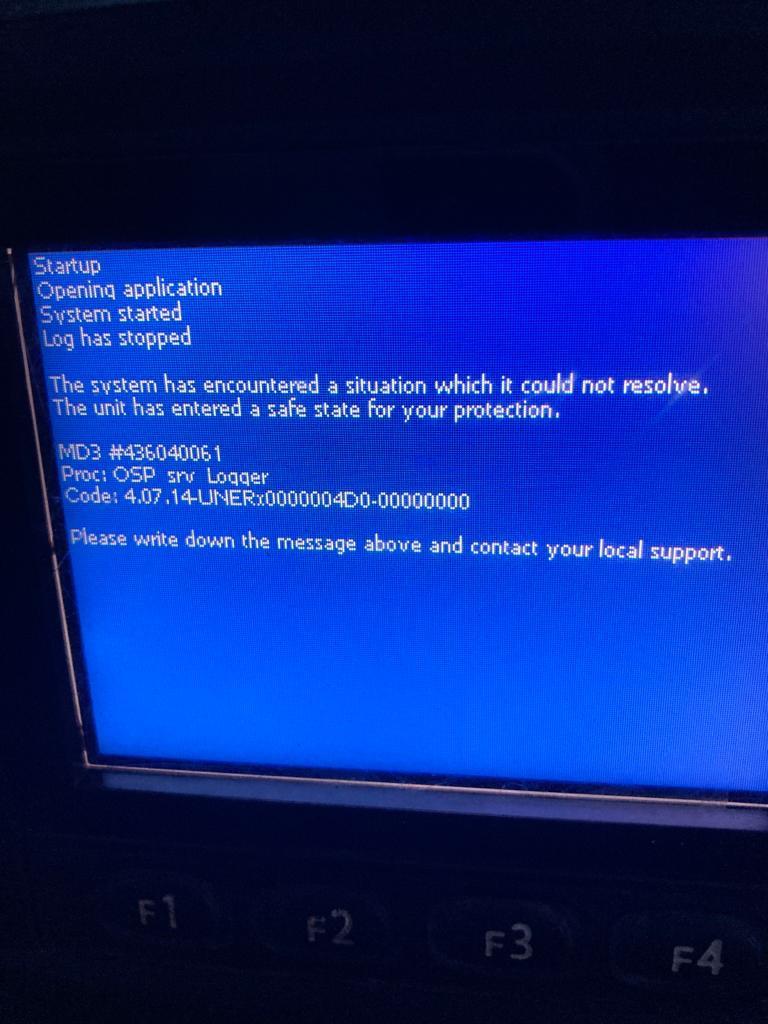

MD3 Stopped - Blue screen error

MD3 Stopped - Blue screen error

Is there a way to fix this - or replace the MD3?

Customer support service by UserEcho