Intermittent overload COUT error

Hi, I have an issue with intermittent MC43 COUT overload errors on one of our machines.

Status is OK and operates well in most conditions, but will randomly report overload (even when that function is not requested).

I have tested the solenoids, plugs, and wiring harnesses within this circuit and all looks ok.

COUT circuit C1:16, 41, 57.

Is there anything else I should check to see what might be going wrong?

COUT open load error calculation

COUT open load error calculation

We have a machine that has sporadic nuisance open load errors on a function controlled by a unidirectional current output (COUT-G) on an MC43. Since this happens with some frequency, I suspect we are right up against the limit of the open load detection threshold. They test out well in assembly, but any increase in resistance occurring in the field might be setting it over the edge of the error threshold.

How can I calculate at what load resistance, commanded current, and supply voltage an open load error will occur?

This function is controlled with a Parker CCP024H 1/2" super coil with nominal resistance at room temperature of 30.30 ohms. Machine runs on 24V (around 28V when alternator charging). Maximum commanded current is set to 600mA.

Using Current Out as 4-20 ma signal for VFD

Using Current Out as 4-20 ma signal for VFD

Are the current out channels on an MC43 suitable for dishing out a 4-20 ma signal? It would be controlling a VFD.

I know the current out channels are typically used to control valves and used in the hundreds of milliamp range.

COUT overload error when PWM HS is shorted to GND

COUT overload error when PWM HS is shorted to GND

We are using a MC43 and using PWM and COUT channels. What we have noticed is when a PWM HS output is shorted to ground, one of our COUT outputs goes into overload. In our case, C2:51 was shorted to ground but C2:67/C2:15 had the overload error.

ID-Tag 4-7 for Molex MX123

ID-Tag 4-7 for Molex MX123

Hello,

ID-tag 4 to 7 does not exist for Molex MX123.

We use 4,5 and 7 today and have to re crimp those ID-Tags for MX123.

When do you plan to offer ID-Tags 4 to 7 for MX123?

Regards

Fredrik Forsberg

MC4X CAN bus labelling different in manual and IQAN Design

MC4X CAN bus labelling different in manual and IQAN Design

IQAN Design refers to CAN bus on the MC4X as A, B, C etc, manual (under installation) refers to it as numbers 1, 2, 3 etc. Although its obvious to work out, its better for us if its one designation across the board to avoid confusion when cross referencing documents.

MC41 losing CAN comms

We are using a MD4-7 and x2 MC41's on some of our machines (we actually wanted to use only x1 MC42 for these jobs but we are still waiting for the parts to arrive and have deadlines to meet so we are just using what we have available to get the job done)

But last night we started testing the machine and went through all of the procedures and functionality when all of a sudden an error appeared on the display telling me that one of the MC41 controller lost comms, but the other one was still fine and giving readings... So the 1st thing we tried to resolve this was typically switching the machine off and on, but this time there was no CAN comms at all.

We went though the wiring harness and made sure that everything was correct and the wiring was all good, so we then went and replaced both these controllers with new MC41's we had in stock, we plugged it in uploaded the software and the system was happy again with the new controllers and it is still working fine at this moment... So I took the 2 faulty MC41's to my office and connected it all together to try and diagnose the issue.

Each time I tried uploading software (using IQANDESIGN 5.01 via ethernet) it kept on warning me about the incomplete system and that only the MD4-7 will be updated.

Eventually we switched from CAN-A to CAN-B only on the MC41's. but upon each attempt to upload the software, the same "incomplete system" warning appeared.

So I just left it for a while and a few minutes later decided to just try again uploading once more. Well it worked all of a sudden and that is also a big problem, because I didn't change anything where I could say " there, that was the problem".

This is worrying us a bit, because we have no idea why this happened in the first place and secondly these machines are going to the middle of Africa... So this sort of thing must not happen at all!

I have only been using MD4's and MD3's with XA2's in the past without any problems at all, these are our first machines using the MC4x family and this is also the 1st time that I encountered any issues like this on IQAN.

Have anyone else experienced this before? I have no idea why it failed or why it started to work again and this is definitely not the correct answer to give the person asking this question when there are deadlines to meet.

The other thing to mention also is the LED's on the controllers which blinked bright yellow 3 times then blinked dimmed yellow 3 times while it was not communicating. which also does not correspond with these fault codes in the manual. There was no RED LED blinking at all.

MC41 not reading specific RPDO from PLC

MC41 not reading specific RPDO from PLC

We have an MC41 connected to a PLC via the CANbus. We push 16 RPDO blocks from the PLC to the MC41. We are on our 10th unit and suddenly on unit #10 we are not getting any values from RPDO 11, and it is greyed out when we look at it with IQANdesign. Help?

Problem using Current CIN sensors

Problem using Current CIN sensors

Hi,

I need some help.

I have trouble using CIN sensors.

I have no problem with any others sensor types, but with almost all current sensors (4-20mA), I get an error with the signal (24mA) after some use.

But not all the time.

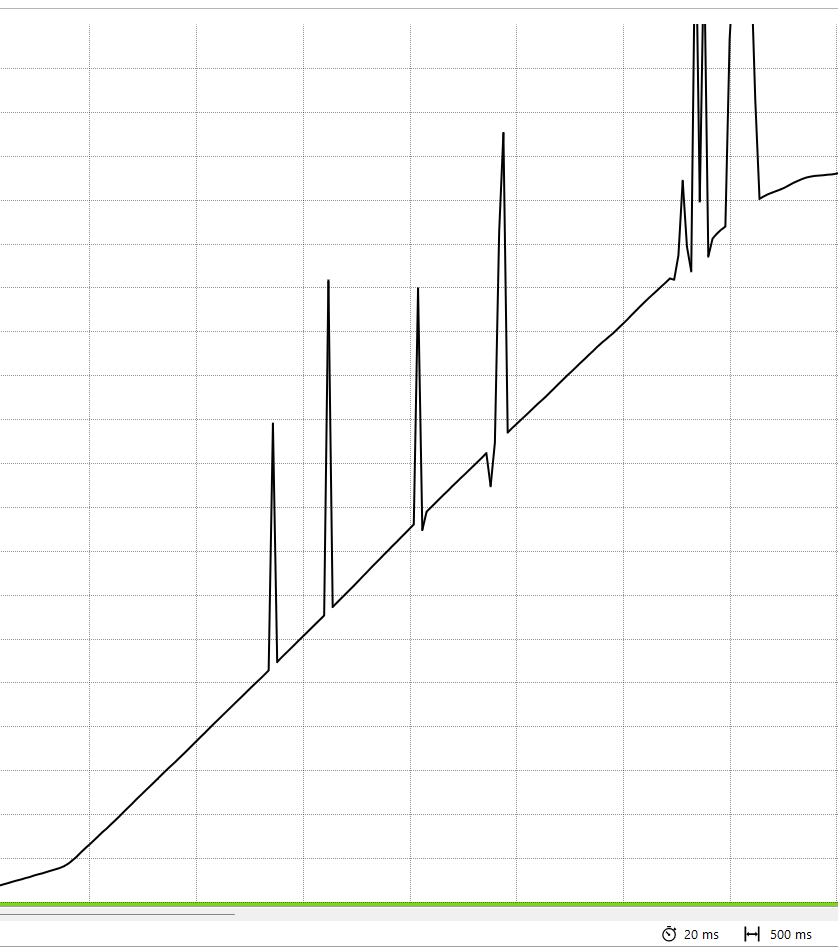

For exemple, here I have some undesired spikes while measuring.

Spikes are very short so I can't read +24mA in IQAN but I think if there was longer, I would have 24mA, so more than my scaled value at 20mA

For this exemple, the value come back to a good value quickly, but sometime it stays in error ~= 24mA

Have you ever had similar problem ?

Do you have some advises ?

I can't use Vref+5V because my sensors can be supplyed between 8-32Vdc.

The sensors used are made with 3 wires : +24V / 0V / Signal

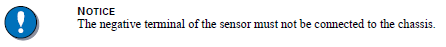

So the wire 0V is connected to the 0V of the battery, but on every machine, the 0V of the battery is conencted to the chassis of the machine.

Iin the manual it is recommanded to do not connect the 0V to the chassis. It's not possible on mobile machine.

So we tried to connect the 0V to the VREF- but it's doesn't work obviously.

Is there a way to have a VREF for sensors that supply about 10Vdc ?

Hope someone has some experiences that can help us to understand this problem with current sensors !

MC42FS Error code R4:2 1:1:3 I/O startup test failed

MC42FS Error code R4:2 1:1:3 I/O startup test failed

Got the R4:2 1:1:3 I/O startup test failed error on a MC42FS module.

Even when I only put power (24v external power supply) and a address tag on it.

Tried to put an empty program on the controller. The controller is installing the program but when it restarts it keeps coming back with the same error.

Is there anything I can try to fix this?

Customer support service by UserEcho