DOUT LS issue with LED

DOUT LS issue with LED

Greetings,

I have 4 LEDs each connected to a DOUT LS channel on an MC43.

The issue I have is they each turn on faintly even when the output is off.

Once the DOUT is on the light appears brighter.

The LEDS themselves are 12V LEDs like this one (though each is a different color):

https://www.factorymation.com/PDA-B12V-B

I don't currently have a Current Limiting Resistor inline, would not having that cause this sort of behavior?

Or is there something else I am missing about operating LEDs off the DOUT channels?

Digital out low side outputs

Digital out low side outputs

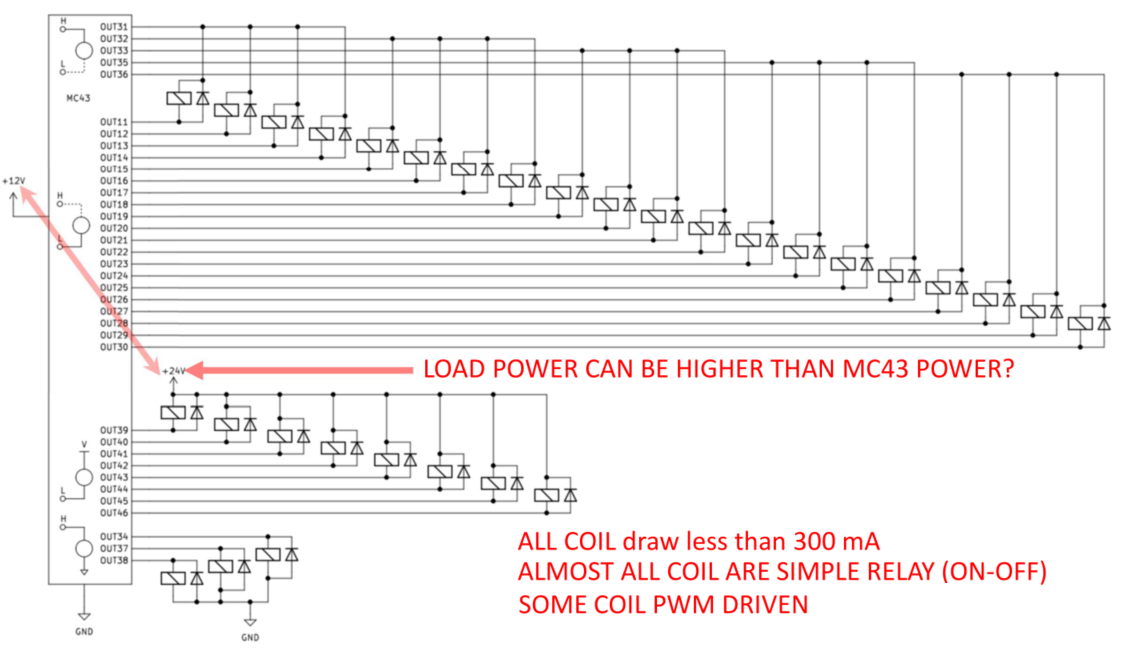

Is this MC43 output configuration is correct?

Can we power a load at higher voltage than the MC43 power for output 30 to output 46?

Fault Capacity of -VREF

Fault Capacity of -VREF

In the IQAN MC4x/XC4x instruction book on page 67, it is recommended that sensors requiring a supply of more than 5V have their returns connected to -VREF instead of chassis ground. I understand the reason for doing this is to minimise sensor error, however, if the sensor supply is shorted to -VREF there will be a large fault current through the -VREF pin. What is the fault current handling capability of a -VREF pin? Furthermore, if this pin is not capable of handling high fault current for the time it takes for a typical thermal circuit breaker to trip, would powering the sensor from a digital output with current limiting be a preferred option?

Can PWM outputs be programmed to send 0-10Vdc signal?

Can PWM outputs be programmed to send 0-10Vdc signal?

I have been doing some research and configuring a CANopen module to send a 0-10Vdc signal to run a prop valve. I have now been told that a PMW output on the MC4x and XC4x can be programmed to output 0-10Vdc. I wanted to confirm that is correct as I have seen in the forum that you are unable to send out that signal type.

Motor control with MC41 in full bridge mode

Motor control with MC41 in full bridge mode

What is the best way connect motor in full bridge mode to MC41?

Controlling 9V/2.7A prop valve with MC4X

Controlling 9V/2.7A prop valve with MC4X

Has anyone tried to control a D1FBE01HC0NMWO (9V/2.7A spool) with a PWMOUT, if so what is the performance like? The rating for COUT is 2.5A so I will have to utilize the PWMOUT HS. I have read that COUTs allow the best performance with solenoid.

PWM Output - Doesn't Work with Low Current Load

PWM Output - Doesn't Work with Low Current Load

I am trying to us a PWM HS Output on an MC4x to drive a signal needed for a PWM fan. I will get an open load when I try to drive it directly, and even with disabling the open load check it still will not work. The output just stays at 12v.

If I add a 1k resistor from the PWM output to ground, everything works as it should. But now the issue I have is with no power to the MC4x, I have some leakage voltage in the range of 50ma which will draw the battery down.

Is this a software or hardware issue that will not allow me to use this PWM output to drive this fan directly??

My work around is using a relay to make and brake the resistor to ground when the MC4x is powered. But this is not a great solution, and would like to see if this is just a software issue that could be fixed.

MC4x parallel HS output usage

MC4x parallel HS output usage

When an MC4x DOUT HS is wired in parallel, are you able to drive a single output as long as the over current limit is not met? What I driving at is activating both outputs initially, and deactivating one later.

MC4x DOUT HS or PWM HS Over current threshold

MC4x DOUT HS or PWM HS Over current threshold

What is the current level that triggers over current diagnostics when HS outputs are used in parallel?

MC43FS VRef+ no output

MC43FS VRef+ no output

Have any idea what is problem cause VRef+ (C1:7) no 5V output. I can comfirm the PIN and controller are ok after i made test on bench.

What is problem cause 5V PIN stop output. possible CAN wrong or Any PINs short to ground ? No error informs why VRef do not output now

Customer support service by UserEcho