Master / Expansion Different -Batt

Master / Expansion Different -Batt

We have a requirement to have multiple XC43 modules remotely to the master MC43FS module. Its likely they will all be powered from separate power supplies and they wont supply the same 0V for batt -ve.

Is this likely to be a problem in terms of interference etc?

Stylus for MD5

Stylus for MD5

Our customer has requested a stylus for interacting with the MD5 we have supplied. Instruction manual states a passive stylus for the MD5, has anyone got any recommendations or experience as to what works best?

MD5 Mounting Clips

MD5 Mounting Clips

Parker # 20085209.

Anyone else receive 3D printed clips?

Surely injection moulded would be the way to go here.

Water will soak into the porous material and the clips will fail?

PWM Output Commanded to 0, but voltage measured at Output

PWM Output Commanded to 0, but voltage measured at Output

IQAN Tech Support,

We are looking for help with troubleshooting our "IQAN Controller, Master Unit, IQAN - MC43" Safety Controller. It is getting inputs from two Temposonics tank-level sensors in our electronic water-level system, models GB Series & RF 5th Gen input sensors. The IQAN controller is PN 20085113.

We are receiving a potential difference (voltage output) of 0.39 V from Output pin to System Ground when measured with a multimeter; however the programming software indicates that the output should be 0 V. Our known inputs and outputs are below:

|

Inputs |

Outputs |

||||

|

I!: Inclinometer |

Connector 1, Pin 26 |

0 – 5 V |

O1: High |

Connector 1, Pin 48 |

0.24 V (Pin-to-Pin) |

|

I2: AFT Level Sensor |

Connector 1, Pin 53 |

4 - 20mA |

O2: Low |

System Ground |

|

|

I3: FWD Level Sensor |

Connector 2, Pin 33 |

4 - 20mA |

***SHOULD BE = 0.0 V Output*** |

||

- The tank level sensors are bottomed-out, as there is no water in the tank.

- With no water in the tank, the IQAN is programmed to output 0% Du Cycle, yielding 0.0 gallons on the display - but there is a .39V measured.

- The lowest water level reading that the sensors could output is 120 gallons, but should read 0.0 gallons below that.

- We are needing help troubleshooting and establishing / calibrating our 0.0 baseline

Questions:

1. Why is a voltage being read at the output, when the program is indicating that it should be zero?

2. Can we create a code or loop in the program to circumvent the small output voltage?

Slow cycle time on MD5

It appears the fastest application cycle time on the MD5 currently is 50ms, which is 5x what it was on the MD4. Is this something that is planned to be improved in a future software or firmware release?

I need to be able to send out 10ms messages and it is just not possible from what I can tell on the the MD5 series.

Larger Program memory

Larger Program memory

For a long time we have been running into the limitation that the Program memory is too small for us. Is there also a view with the new MC4x to increase this in the future to 3Mb for example, this would help us enormously in adding functions that we are now forced to leave on the shelf.

MD4 and hydrogen sulfide (H₂S) exposure

MD4 and hydrogen sulfide (H₂S) exposure

We have experienced issues with two MD4-10 units where the touchscreens have become unresponsive. These master modules were being used on two different underground mining machines, operating in the same area of the mine with high levels of H₂S. Could there be a correlation between H₂S exposure and the touchscreens becoming unresponsive?

MC43 Reports Vref error cannot measure

MC43 Reports Vref error cannot measure

Good morning. I have and MC43 and MD4 running on a machine that is programmed in 6.08.32. I am getting random MC43 Vref B error codes along with the errors for the switches and transducers connected to that Vref.

When I record a plot graph of the MC43 diagnostic channel attached to the Vref, input voltage, and the input voltages for all the sensors, I am not able to record any change in the voltages that would indicate a Vref issue. Has anyone else ran into this issue?

Touchscreen glove compatibility

Touchscreen glove compatibility

We have a customer that requires a certain type of PPE glove to be used when operating MD5 HMI. The system we have planned is using 10" display but we don't currently have a unit here to trial, instead I have tried a MD5-5 with the certain glove type and it works OK.

Is the 10" version just a scaled 5" and therefore I can assume as long as it works with the 5" it will be fine with the 10" version? I guess it depends if the same manufacture and screen tech is shared between the different modules?

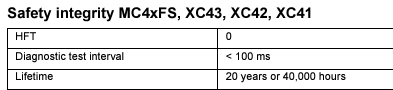

Lifetime of MC43FS

Lifetime of MC43FS

We have a project that is to be used for the next 40 years. It is a functional safety system that utilises MC43FS. These modules will likely be superseded multiple times (probably due to enhancements in electronics etc) after the 20 years lifetime shown in the manual:

To guarantee functional safety, presumably its recommended we remove and replace the MC43FS after 20 years as described in the manual regardless if the module is working correctly? I'm trying to avoid re-assessing the system in 20 years time and fitting a safety controller available in 2045. Therefore I intend on having a brand new MC43FS available for when the system needs a replacement module in 2045.

Is the 20 years triggered as soon as the module is powered up, therefore we would need to clone the software only when we want to replace the module in 2045 (rather than installing software now and starting the 20 years timer)? Or has the module 20 years been triggered from manufacturing date on the serial number?

Customer support service by UserEcho