F3+F4+Up buttons problem in MD3.

F3+F4+Up buttons problem in MD3.

I am using IQAN design V3.19.7.4013. When I pressed F3+F4+Up buttons in MD3 same time, openning the main menu page. But I don't want this. This is a problem for me. What can I do for this.

You can see this problem the following video.

Ethernet Communication Port

Ethernet Communication Port

With the new MC42 and MC43 master modules, I see you have the ability to communicate via Ethernet communication port. Where can I find this part?

MC41 as slave

MC41 as slave

Hi

It will be possible use MC41 IQAN module as a slave?

How use MC41 and Panel MD3 together in same project?

MC3 Current Consumption (and any other module)

MC3 Current Consumption (and any other module)

Does the current consumption of the module (170mA @ 24V) increase if we start connecting sensors on the VREF pins or does this value include the max draw on both the VREF (140mA x 2)?

Does this apply to all master / expansion modules?

Measurement of current consumption on MC3 Vref

Measurement of current consumption on MC3 Vref

Is there a way of detecting how much current draw there is on the VREF supply on an MC3?

I have experimented with a SIL2 pressure transducer connected to an MD4 (don't have an MC3 to hand) and noticed that disconnecting the -VREF and leaving +5V supply and VIN signal wires connected to the controller will generate 2500mV signal into the MD4 VIN. This is not desirable as it simulates a pressure in the system which is not true. I can only imagine its how the internal electronic circuit is manufactured inside the transducer causing the false signal, but its not unique to one manufacture of pressure transducer. The current consumption of the sensor drops from 6mA to zero when the -VE is removed, wondered if this would be a good way to detect disconnected -VREF connection?

Aside from the method above or monitoring for a sudden change in VIN signal within the software, can anyone suggest any other solution to this issue?

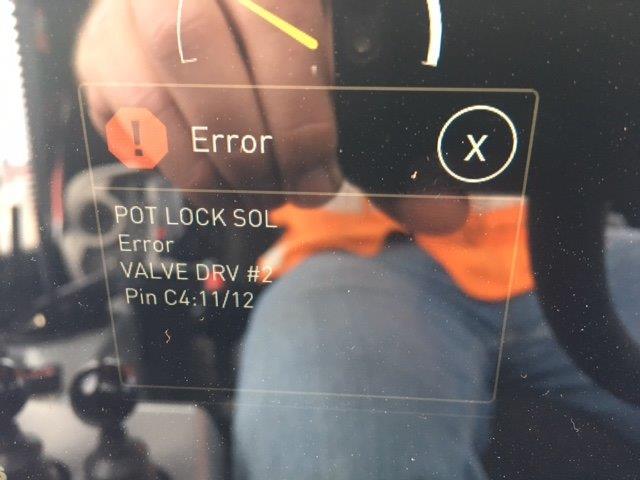

MC3 Output Error on Start Up

MC3 Output Error on Start Up

One of our field units is getting the an "Error" on start-up. It occurs on every startup.

After the error is cleared, everything is working fine. The solenoid(s) showing the error function with no issue.

In the past we have seen open load and overload output errors but not just a generic error message. We replaced the MC3 module and the problem was resolved.

Just curious on what this means? Thanks

MC3 Module Input Error

Hello,

I have a drill rig (Geoprobe 6712DT) which has an MC3 Module installed. Recently, the hydraulic pump would intermittently would stop building operating pressure, and the only workaround I can find is to bypass the MC3 Module and manually force the pump to build pressure. The Module is giving me a 1:2 error code, or "Input" error. Could someone help elaborate what this error could mean in the general sense? Any info would probably help with my troubleshooting. I'm guessing it could be something as simple as a loose wire, but I can't seem to find any so far.

The drill rig comes with the MC3 Module installed, and has worked fine up until recently. The manufacturer doesn't really provide any troubleshooting in regards to said module, so I'm kind of just winging it. The manual for the module tells me that it is an Input Error, but I'm not really sure what could be causing that.

Thanks in advance for anyone who can help me out. My apologies for being somewhat ignorant as to this thing... I'm just a humble driller.

MDL2 Log Error - Failed writing

MDL2 Log Error - Failed writing

A 5 year old MDL2 is giving us this exact (system) pop-up message:

"

Log error

Failed writing. The log has been stopped!

"

My guess is that the (flash?) memory is full or corrupted, so system events like a startup or sensor error can't be written anymore. Not a big deal, but:

* How to get rid of the message

* In case the log memory is corrupt, would that also threaten other memories? In other words, should we replace this MDL2?

As far as I can see, this a fixed system message, not a custom pop-up.

Blank MD4 SCreen at start-up

Blank MD4 SCreen at start-up

I am using an MD4-7 screen on a test bench. 3 out of 4 starts I get either a White Screen or a black screens with some colored dots. Once I saw what seemed to be blocks of black and white.

Looks like the video driver is not starting properly. The application appear to be running since the canbus messages are being generated.

Can this be caused by the regulated switching power supply during start-up or do I have a defective MD4 screen?

Thanks for your inputs.

Ethernet port introduce to other master modules

Ethernet port introduce to other master modules

Is there any plan to introduce Ethernet port to other master modules than MD4? It is quite a good feature in my opinion,

Customer support service by UserEcho