MC2 controller red led flashes rapidly

MC2 controller red led flashes rapidly

Hi

We have a MC2 controller that works normally for some time then it stops. It works again after power cycling it. The led flashes in a pattern not in the instruction book. It just flasher red very rapidly. Any idea on what the cause can be?

TOC2 mechanical adjustment issue

Hi,

Recently I had to adjust ramp values on TOC2 system using by screwdriver.

The whole crane control system has two TOC2 modules and I succeeded to adjust the first one.

When I tried to adjust the second TOC2 module by pressing the push button, all A and B LED's start flashing but I couldn't choose the particular function by moving the control lever. It just stayed on that Auto select mode without responding to any movements. The crane moved anyway during the adjustments and at normal operation mode corresponding LED illuminated.

I connected the TOC2 to IQAN develop and ensured that "adjustable" button was enabled on output channel, and it was.

Also, something unexpectable happened after I got the program from the first TOC2 and didn't send it back nor changed anything on it. As a result, I lost the ability to adjust it by screwdriver anymore and the values were changed.

Eventually I managed to adjust correct values via IQAN develop but the mystery of manual adjusting is unsolved.

Has anyone faced this kind of problem before?

- Markus

Clone display to iPad/mobile/3rd Party display

Clone display to iPad/mobile/3rd Party display

Hi,

Are you aware of any solutions to use a mobile or any 3rd party display to present the information that's visible on the MD4. No input are supposed to take place, its more about presenting data visible to people around the machine. In this case a saw mill where the MD4 are located inside a control room limitied to the operator.

Ideal would be to have a wireless solution.

/JM

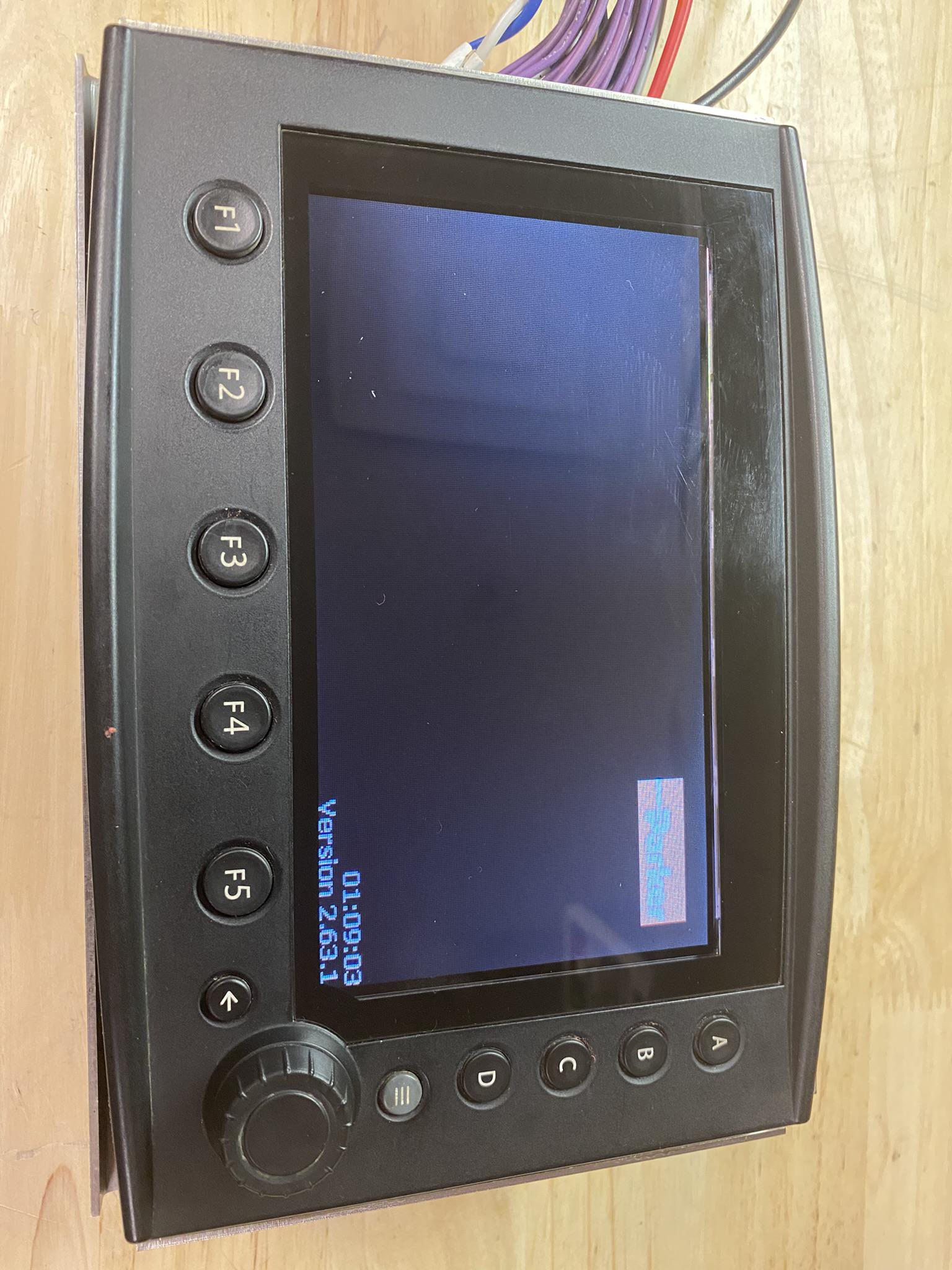

MD4-7 Display stuck into restart mode

MD4-7 is stuck into this mode even when power cycling display. Anyone had si

milar issue? Any suggestion would help.

MC4x parallel HS output usage

MC4x parallel HS output usage

When an MC4x DOUT HS is wired in parallel, are you able to drive a single output as long as the over current limit is not met? What I driving at is activating both outputs initially, and deactivating one later.

MC4x DOUT HS or PWM HS Over current threshold

MC4x DOUT HS or PWM HS Over current threshold

What is the current level that triggers over current diagnostics when HS outputs are used in parallel?

MC43FS VRef+ no output

MC43FS VRef+ no output

Have any idea what is problem cause VRef+ (C1:7) no 5V output. I can comfirm the PIN and controller are ok after i made test on bench.

What is problem cause 5V PIN stop output. possible CAN wrong or Any PINs short to ground ? No error informs why VRef do not output now

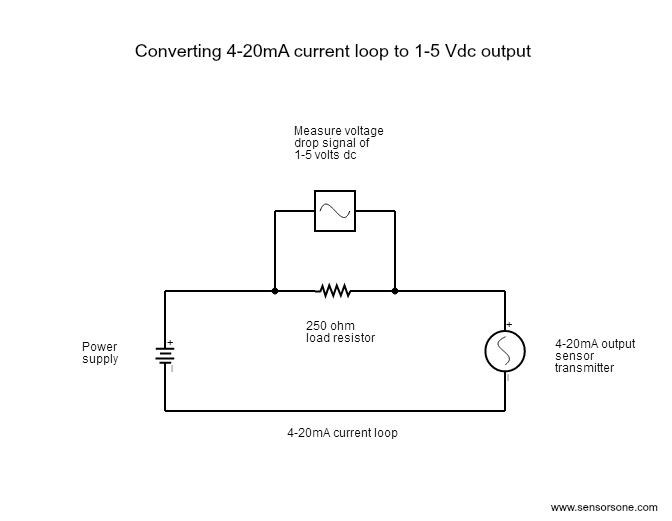

4-20mA convert to V input on MC43 using 250ohm resistor

4-20mA convert to V input on MC43 using 250ohm resistor

When using a high precision 250 or 120ohm resistor to allow IQAN to measure the signal from a current loop, do I need to connect Vref -VE for ground reference?

Any technical reason for using both +BATT pins on MC43?

Any technical reason for using both +BATT pins on MC43?

We have specified an MC43 over the lesser modules in the range because of the additional inputs we need to monitor in the controller. We are not using any outputs on the module therefore current draw is minimal.

Is the only reason there is a second power supply pin (+BATT) to drive the additional outputs that can be configured on the MC43? Because we are not using any outputs (therefore current draw is hardly anything) can we connect only one of the +BATT pin to the supply, is there any technical reason why this cannot be done? I don't have a module to hand but I assume they are internally connected? is there a current limit on the module outputs if we only connect one pin?

I have had a look through the manual, the diagram on page 58 suggests we need to connect both pins on MC43 module only.

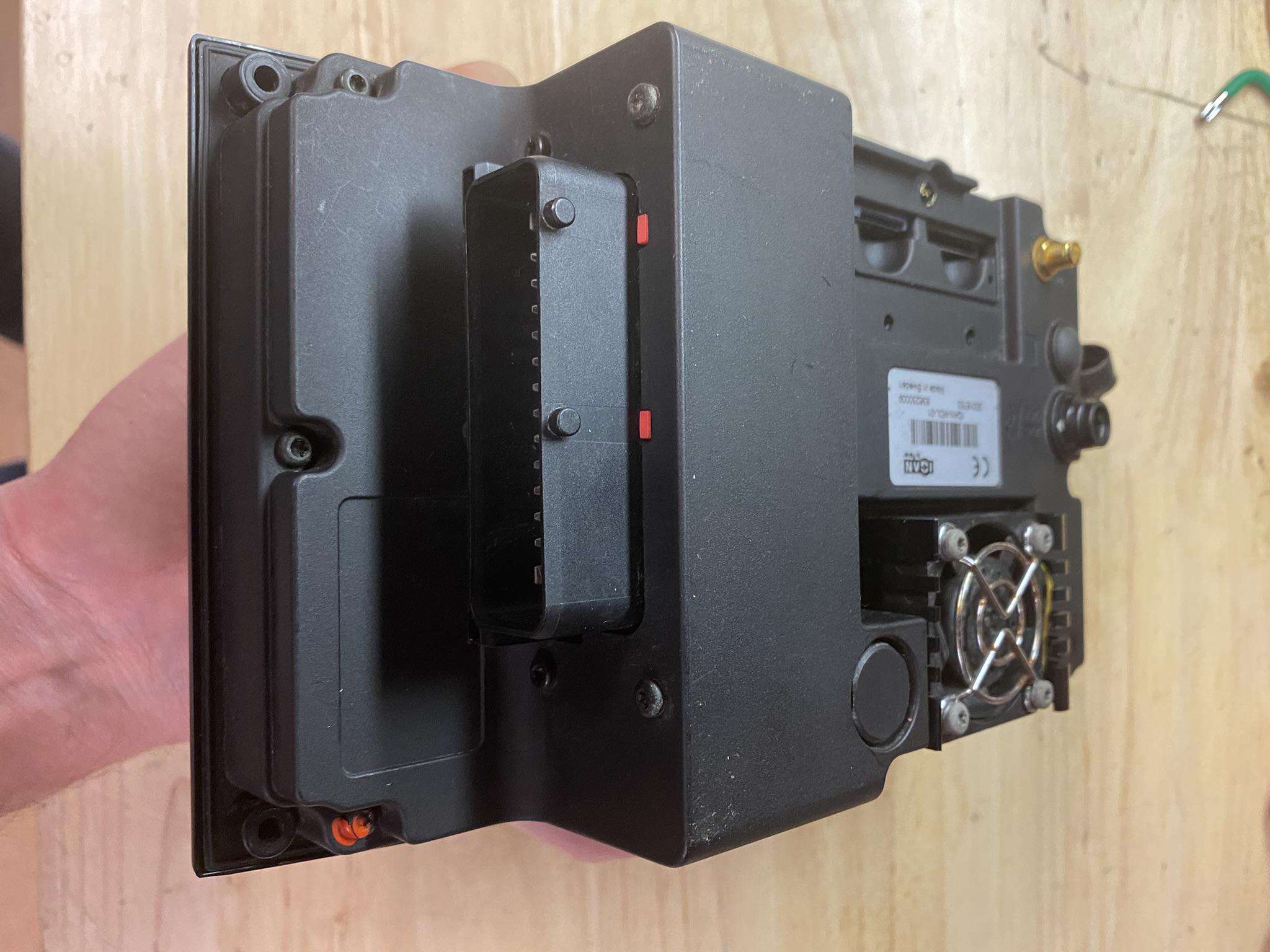

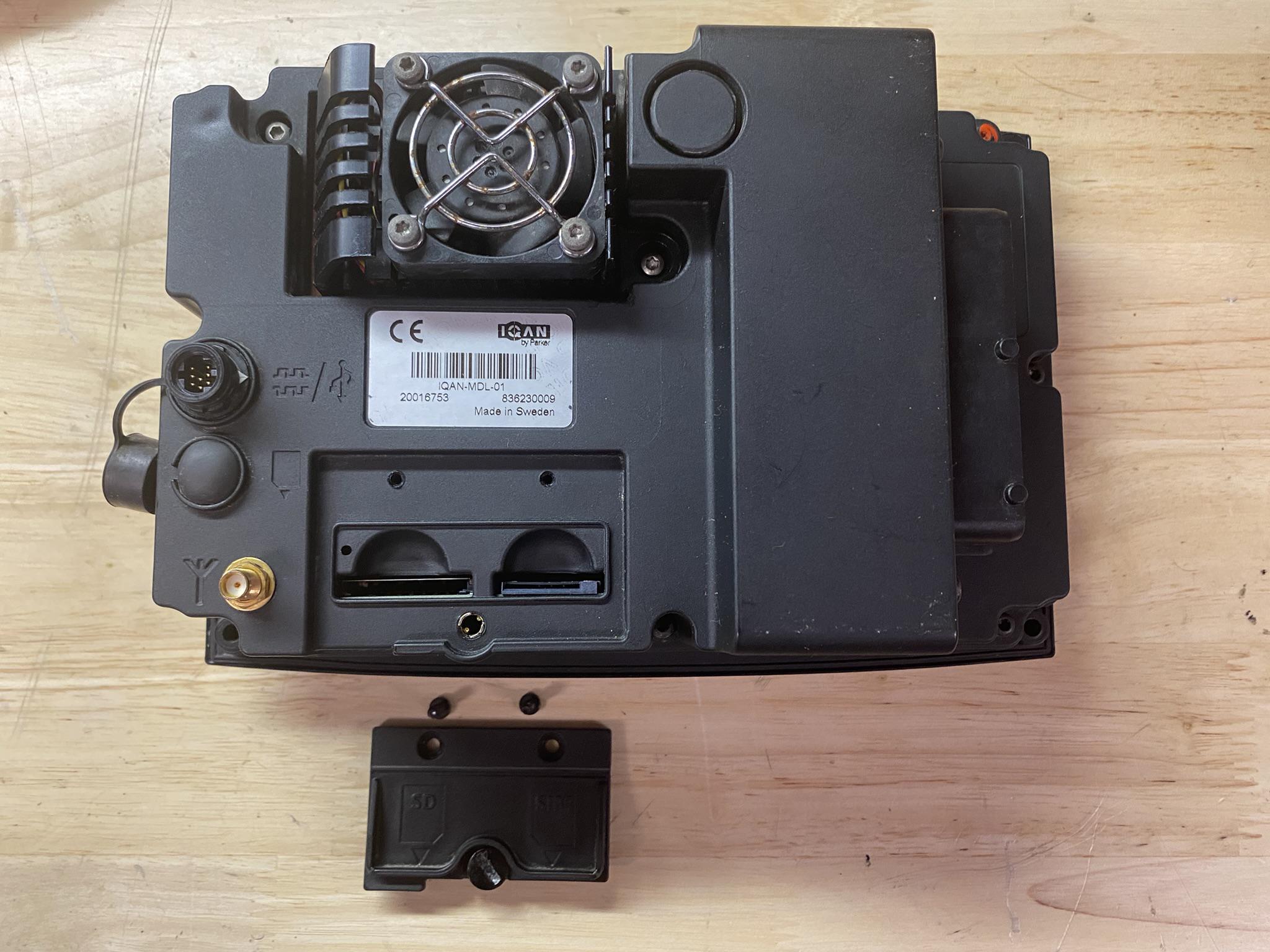

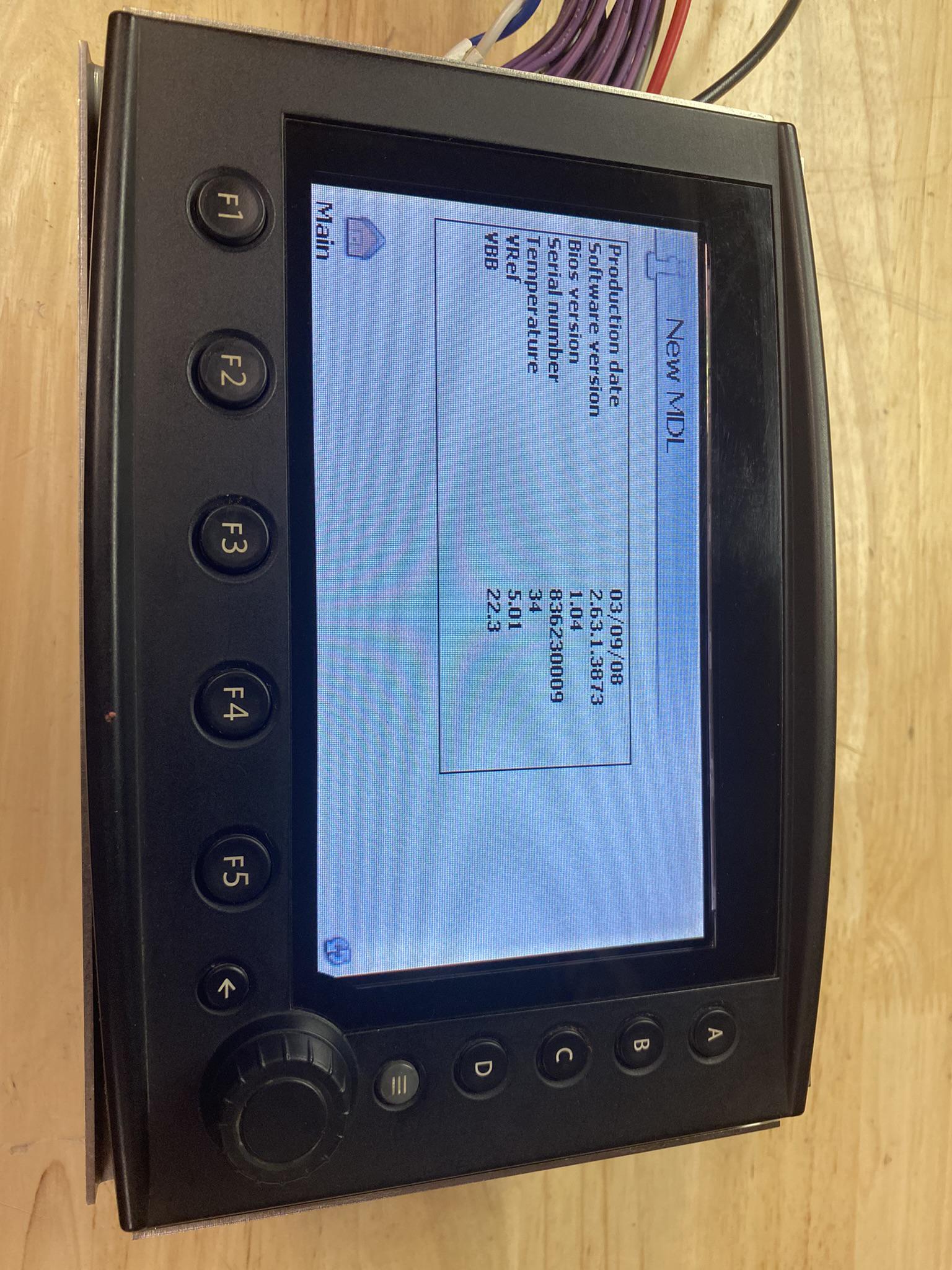

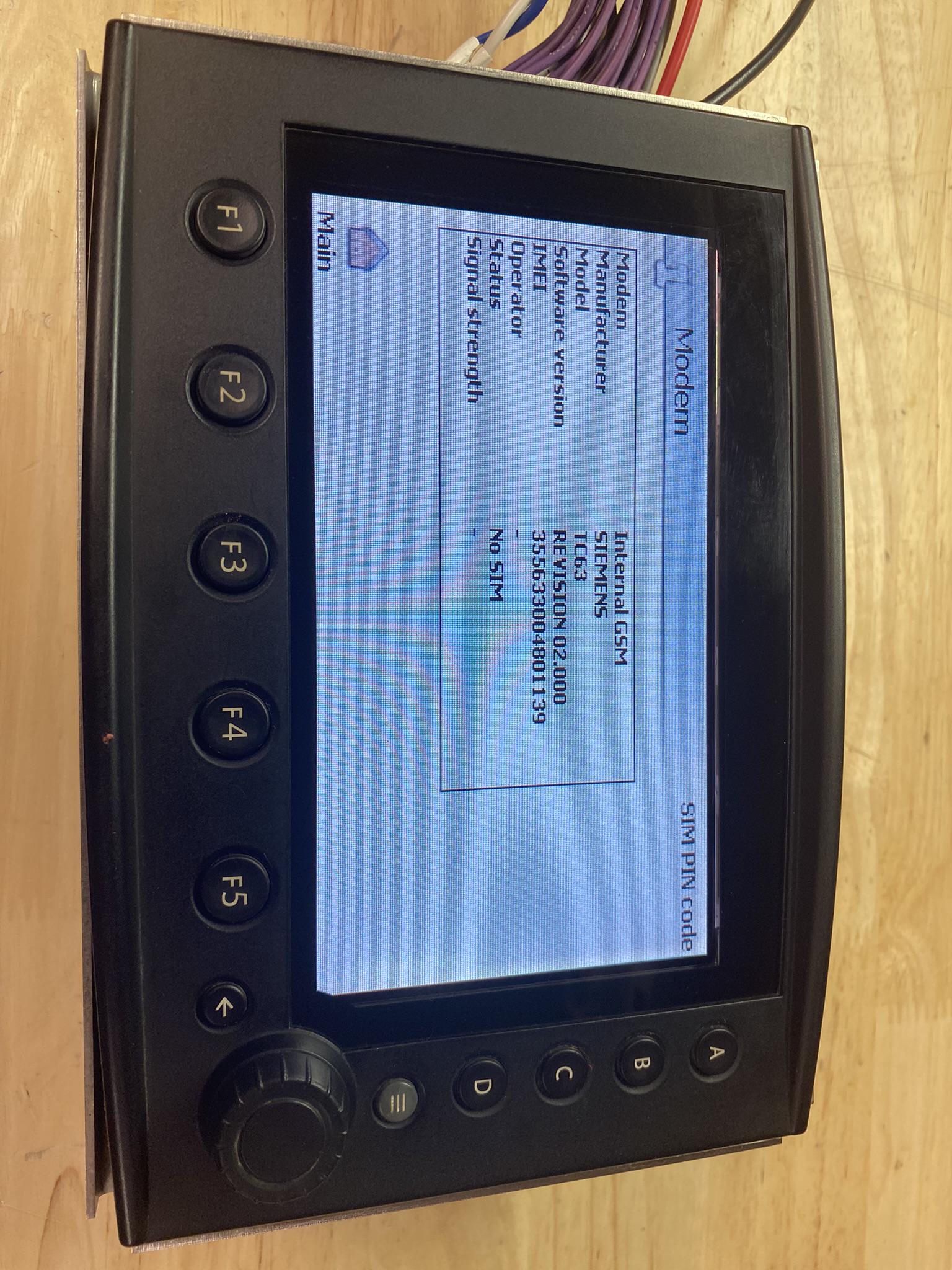

Used MDL2 modules

Used MDL2 modules

I have 4 used MDL2 modules (one with sim port, three without). If you are looking online and can't find them, let me know.

Customer support service by UserEcho