I have an IQAN-MD3 that on start up gives System message "Safe mode. Application not loaded." I have multiple employees using this device, therefore can't get an answer about what circumstances may have created this... How can I get it to Startup?

I have an IQAN-MD3 that on start up gives System message "Safe mode. Application not loaded." I have multiple employees using this device, therefore can't get an answer about what circumstances may have created this... How can I get it to Startup?

MDL2 error code on start up

Hi,

I have an old machine using the MDL2 master module and on start up it is showing blue screen error:

Proc: OSP sys MainProcess

Code: 3.17.2-BUS2-800631BA

Is there any way to salvage this (delete logs?), or has this unit served its time and is on its way out?

Thank you.

Project Documentation Error

Project Documentation Error

Good Morning,

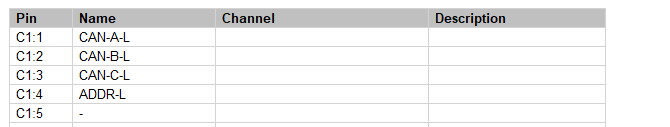

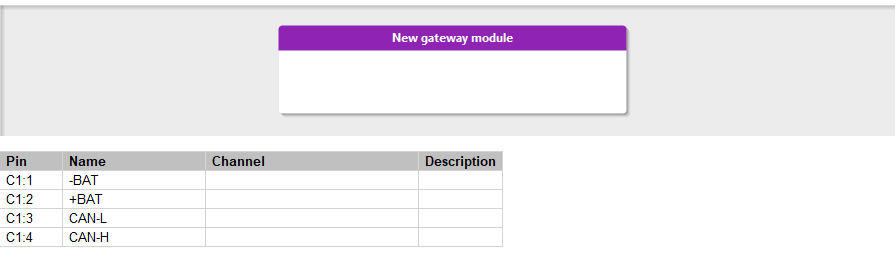

I have completed my first project in IQAN Design and while looking at the project documentation, I noticed what would seem to me like an error. Please see the attached screenshots on how the one pin list shows pin C1:4 under the Master Module as being ADDR-L and under the Gateway module it shows C1:4 as being CAN-H. What am I missing?

LC6 Joystick VREF Connection

LC6 Joystick VREF Connection

I have an application that uses 2 x LC6 joysticks for driving a safety circuit. Primary signals are fed into MC41FS and secondary comparison channel into XC21. I used XC21 as there are not enough VIN into MC41 - 8 x 2 = 16VIN (we have space restrictions preventing bigger or multiple MC4 module).

Modules share the same power supply and are located next to each other, but power supply to joystick (VREF+ & -ve) comes from MC41 module. Secondary comparison VIN into XC21 has no VREF-ve. To prevent fluctuations on VIN on XC21 do I link VREF- between MC41 and XC21?

Current leakaje XC42/43/44

Current leakaje XC42/43/44

Hello, I have a current leakage problem in the XC-43 and XC-44 modules.

I am using Digital Out HS outputs to drive LED blinkers, but they don't turn off completely, there is a 5.8V voltage leakage. The flywheel diode is installed but we have had to install some power resistors in parallel to get them to switch off completely. The same problem has appeared when connecting a buzzer to Digital Out HS.

MD4-7-T1E2 vref error A

We powered up 5 new systems, all identical programming and 2 of the displays show this error.

We aren'y connected to the VREF A. We're trying to get some factory support but haven't been able to get any response on this.

Can I have 24 Volt COUT if I have 12 Volt Power Supply?

Can I have 24 Volt COUT if I have 12 Volt Power Supply?

I may have missed it in the training on IQAN Design, but is it possible for me to have a 24V COUT from an XC43

if I have only a 12V battery supply?

XA2

XA2

hello,

i am this XA2 error in one of our 7ech forklifts, the machine is fully operational, but this error keeps on popping up ‘VREF error Value 4.98v’ can anyone explain why?

XA2 VREF supply more than 5V?

Hello,

I encountered a strange problem with XA2 module.

For some reason the VREF voltage fluctuate between 5 to 5,5Volts and due to that all the VIN-channels turns on simultaneously around 0 to 30% and the crane moves without touching levers.

Replacing XA2 module didn't solve the problem.

Is it possible that there could be some grounding issues in VREF circuit or has the MD3 display unit any affect on XA2 VREF circuit?

- Markus

Customer support service by UserEcho